-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

OTHER SERVICE

FABRICATION

Molding/Machining/Wet Heat Aging Of Plastic Specimens

Resin materials have many advantages. They are lightweight, easy to mold, and highly resistant to water, oil, and chemicals, resulting in a variety of applications in industrial products. The JIS and ASTM standards for plastic testing have been incorporated into ISO standards. KMTL injection-molds and machines JIS and ISO standard specimens and various specimens for physical properties testing.

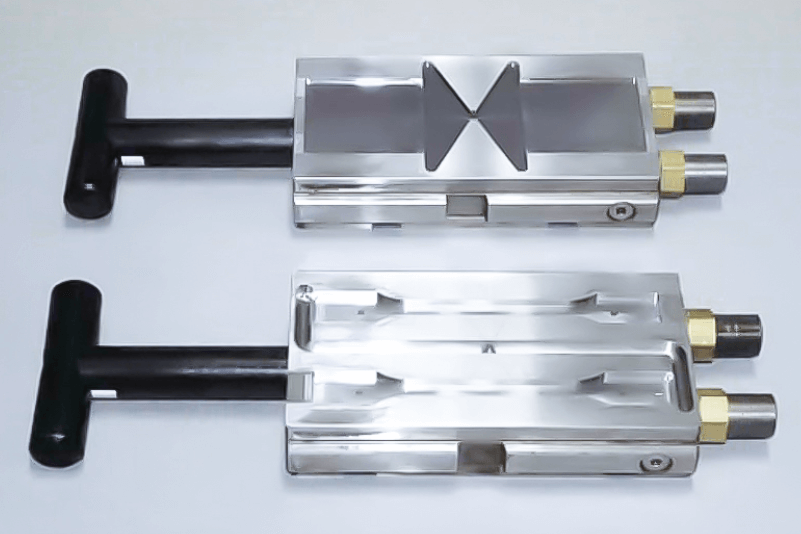

D2 and ISO-A type Injection molds

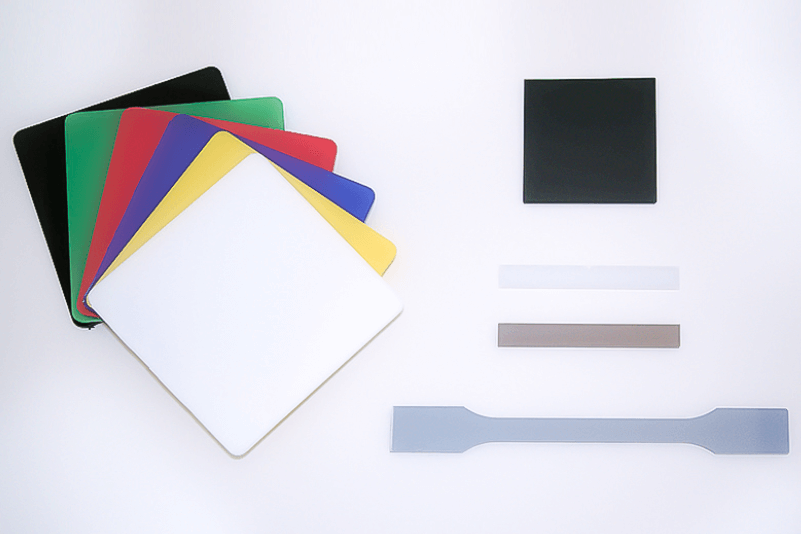

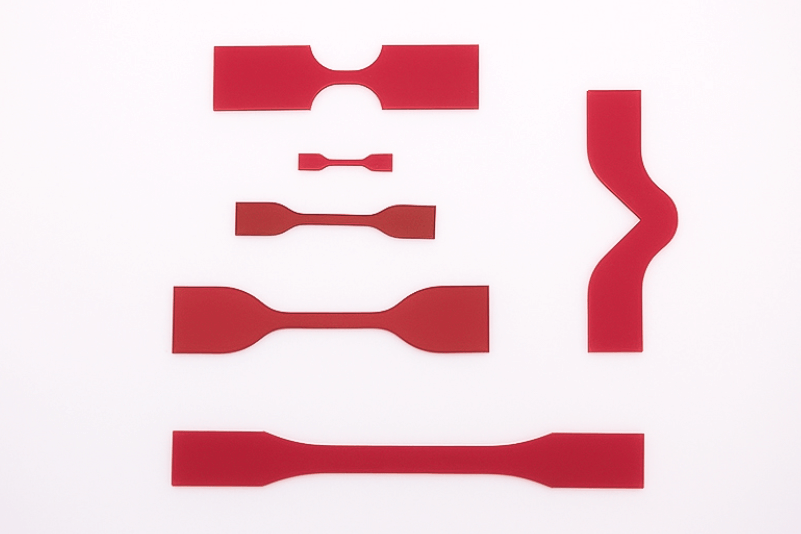

Injection molded specimens

Die-blanked specimens

Main equipment

| Injection molding |

|---|

| ISO-specimen injection molding machines | |

|---|---|

| Model: ISO100GN Resin temperature: 180 to 300℃ Clamping force: 1010kN Injection ratio: 151cm³⁄s Screw diameter: 32㎜ | Mold: ISO-A, ISO-B, ISO-D1, ISO-D2, 3-mm thick plate (100×100㎜), 4-mm thick plate (100×100㎜) |

|---|---|

| Model: EC100SX-2A Resin temperature: 300 to 500℃ Clamping force: 980kN Injection ratio: 161cm³⁄s Screw diameter: 32㎜ | Mold: ISO-A, ISO-D2 |

| Machining |

|---|

| Notched impact specimen Bend specimen |

|---|

| Brittleness temperature specimen Elastomer specimen blanking |

|---|

Standards

| Injection molding |

|---|

| JIS K 7152-1 |

| ISO 294 |

TEST SERVICE

Other Service

KMTL also support the production of test pieces and various equipment required for testing and analysis and provide total support for material testing.

Test Specimen Preparation

Sophisticated Machining Skills

Sampling and Machining Miniture Test Specimens