-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

ACCREDITATIONS / APPROVALS

ACCREDITATIONS/APPROVALS

Accreditations/Approvals

KMTL’s management method is based on globally recognized ISO 9001 and ISO/IEC 17025 to meet the requirements of the nuclear industry, aircraft industry, and a wide variety of fields. Also, we are the first material testing laboratory in Japan to be accredited to Nadcap (a special process accreditation program in the aerospace industry).,

We believe the quality management system is of utmost importance in meeting the needs of our customers. The quality assurance is at the core of our services– testing, machining, designing and analysis–to continuously meet the expectations of customers worldwide.

JIS Q 9001 and JIS Q 9100

In addition to ISO 9001:2000 (Quality Management System)confirming our, credibility as a laboratory, we obtained certification to JIS Q 9100,which has higher trust from the aerospace industry,in 2005.

JIS Q 9100 was established in Japan as the quality management system standard for the aerospace and defense industry.Equivalent standards are AS 9100 in North America and EN 9100 in Europe. JIS Q 9100 includes requirements specific to the aerospace and defense industry in addition to requirements of ISO 9001.

| Certification body | Japan Quality Assurance Organization (JQA) |

|---|---|

| Certification number | JQA-QMA16298(ISO 9001) JQA-QMA12316(ISO 9001) JQA-AS0019(JIS Q9100) |

JIS Q 17025(ISO/IEC 17025)【Mechanical Testing, Chemical Testing】

ISO/IEC 17025 is an international standard specifying, general requirements for the competence of testing and calibration laboratories. This accreditation, officially ensures that a laboratory has the competence to carry out specific tests and/or calibrations. Test certificates issued by a laboratory accredited by based on the accreditation from JAB are accepted worldwide through mutual recognition agreements.

KMTL was first accredited to this standard in 1998. The present accreditation scope is as shown below.

| Accreditation Body | Japan Accreditation Board(JAB) |

|---|---|

| Accreditation No. | RTL00430 |

The scope of accreditation for Harima Workshop:

M25

Mechanical testing

| – |

|---|

M25.A1.1

Iron and Steel/Non-ferrous Metal

| – |

|---|

B13.1

Tensile Testing

| JIS Z 2241 |

|---|

| ASTM E8/E8M |

| JIS G 0567、ISO 6892-2 |

| EN 10002-5、ASTM E21 |

| ISO 6892-1 |

| JIS Z 3121、ISO 4136、EN 895 |

| ASTM B557/B557M |

| ISO 6892-3 |

B13.3.1

Bend testing

| JIS Z 2248 |

|---|

| ISO 7438 |

| JIS Z 3122 |

| ISO 5173 |

| EN 910 |

B13.4.1

Charpy impact test

| JIS Z 2242、EN 10045-1、ISO 148-1 |

|---|

| ASTM E23 |

B13.6.1

Brinell hardness test

| JIS Z 2243-1、JIS Z 2243-2、ASTM E10 |

|---|

B13.6.2

Vickers hardness test

| JIS Z 2244、ISO 6507-1、ISO 6507-4 |

|---|

| ASTM E384(except Knoop hardness) |

| ASTM E92(except Knoop hardness) |

B13.6.3

Rockwell hardness test

| JIS Z 2245 |

|---|

| ASTM E18 |

B13.5.1

Fracture toughness testing

| JIS G 0564、ASTM E399 |

|---|

| ASTM E1820、E1921 |

B13.5.2

Drop-weight test

| ASTM E208 |

|---|

B13.15.1

High-cycle fatigue testing

| ASTM E466 |

|---|

B13.15.2

Low-cycle fatigue testing

| JIS Z 2279 |

|---|

| ASTM E606/606M |

B13.15.6

Crack growth test

| ISO 12108 |

|---|

| ASTM E647 |

B13.16.1

Tensile creep testing

| JIS Z 2271、ASTM E139、ASTM E292 |

|---|

B2.1

Metallographic test

| ASTM E3 |

|---|

B2.1.1

Macroscopic examination

| JIS G 0553、ASTM E340 |

|---|

| EN 1321、ISO 17639 |

B2.1.2

Microscopic examination

| ASTM E407、EN 1321 |

|---|

| ISO 17639 |

B2.1.3

Grain size determination

| JIS G 0551、NF EN ISO 643(Specimen adjustment: except heat treatment method) (Evaluation method: except counting method) |

|---|

| ASTM E112(Specimen adjustment: except heat treatment method) (Evaluation method: except planimetric procedure) |

| ASTM E930 |

B2.1.4

Microscopic test for the non-metallic inclusions

| JIS G 0555 |

|---|

| ASTM E45( Method A, Method D) |

B5.15

Heating and temperature tests

| Heat treatment of specimen (KQW-BQ005) |

|---|

M25.A1.2

Fasteners

| – |

|---|

B2.2.2

Determination of decarburized depth

| JIS B 1051 (9.10.2) |

|---|

M25.A2.1

Plastics

| – |

|---|

B13.1

Plastics Tensile Testing

| JIS K 7161-1、JIS K 7161-2(except Poisson’s ratio) |

|---|

B13.3.1

Plastics Bend testing

| JIS K 7171 |

|---|

B13.4.1

Plastics Charpy impact test

| JIS K 7111-1 |

|---|

B13.4.2

Plastics lzod Impact strength test

| JIS K 7110 |

|---|

B13.6.3

Plastics Rocwell hardness test

| JIS K 7202-2 |

|---|

M25.A13

Composite Material

| – |

|---|

B13.1

Tensile strength & elongation test

| ASTM D3039/D3039M (except Poisson’s Ratio, Transition Strain) |

|---|

B13.2.1

Uniaxial compression

| SACMA SRM1R |

|---|

| ASTM D6641/D6641M (except Poisson’s Ratio) |

B13.8.2

Shear characteristic test

| ASTM D2344/D2344M |

|---|

| ASTM D3518/D3518M |

M26

Chemical Testing

| – |

|---|

M26A1/B1.2

Metal: Iron and steel

Volumetric analysis I (titration)

| JIS G 1216-2 |

|---|

M26A1/B1.2

Metal: Iron and steel

Volmetric analysis I(Redox titration)

| JIS G 1217 4. a) |

|---|

M26A1/B2.1

Metal: Iron and steel

Absorptiometric analysis: Infrared spectrophotometric analysis

| JIS G 1211-3[except 8.2 a),b)] |

|---|

| JIS G 1215-4 (except 10.1, 10.2) |

M26A1/B2.1

Metal: Iron and steel

Absorptiometric analysis: UV-visible spectroscopy

| JIS G 1213 4. b)、JIS G 1214 4. a) |

|---|

| JIS G 1212-2 |

M26A1/B2.4

Metal: Iron and steel

Emission spectrochemical analysis: ICP-AES

| JIS G 1258-1、JIS G 1258-2*Partially modified. |

|---|

| JIS G 1258-3*Partially modified. |

| JIS G 1258-5 |

M26A1/B4.3

Metal: Iron and steel

Thermal conductivity measurement: Thermal conductivity method

| JIS G 1228-3*Partially modified. |

|---|

M26A1/B1.2

Metal: Nickel alloy

Volumetric analysis I (titration)

| JIS G 1216-2*Partially modified. |

|---|

M26A1/B1.2

Metal: Nickel alloy

Volmetric analysis I(Redox titration)

| JIS H 1279 4. b)*Partially modified. |

|---|

M26A1/B2.1

Metal: Nickel alloy

Absorptiometric analysis: Infrared spectrophotometric analysis

| JIS H 1275 4. e)、JIS H 1277 4. d) |

|---|

M26A1/B2.1

Metal: Nickel alloy

Absorptiometric analysis: UV-visible spectroscopy

| JIS H 1276 4. b)、JIS H 1278 4. a) |

|---|

M26A1/B2.4

Metal: Nickel alloy

Emission spectrochemical analysis: ICP-AES

| JIS H 1289*Partially modified. |

|---|

M26A1/B4.3

Metal: Nickel alloy

Thermal conductivity measurement: Thermal conductivity method

| JIS G 1228-3*Partially modified |

|---|

The scope of accreditation for Ibaraki Workshop:

M25

Mechanical testing

| – |

|---|

M25.A1.1

Iron and steel/Non-ferrous Metal

| – |

|---|

B13.1

Tensile Testing

| JIS Z 2241、ASTM E8/E8M |

|---|

| JIS Q 0567 |

| ASTM E21 |

| JIS Z 3121 |

| ASTM B557/B557M |

| ISO 6892-1、ISO 6892-2 |

B13.3.1

Bend testing

| JIS Z 3122 |

|---|

B13.4.1

Charpy impact test

| JIS Z 2242、ISO 148-1 |

|---|

B13.6.1

Brinell hardness test

| JIS Z 2243-1、JIS Z 2243-2、ASTM E10 |

|---|

B13.6.2

Vickers hardness test

| JIS Z 2244-1、JIS Z 2244-2、ASTM E92(except Knoop hardness) |

|---|

B13.6.3

Rockwell hardness test

| JIS Z 2245 |

|---|

| ASTM E18 |

B13.5.1

Fracture toughness testing

| ASTM E399 |

|---|

| ASTM 1820、ASTM E1921 |

B2.1

Metallographic test

| ASTM E3 |

|---|

B2.1.1

Macroscopic examination

| JIS G 0553、ASTM E 340、ISO 17639、EN 1321 |

|---|

B2.1.2

Microscopic examination

| ASTM E407、ISO 17639、EN 1321 |

|---|

B2.1.3

Grain size determination

| JIS G 0551、NF EN ISO 643 (Specimen adjustment: except heat treatment method) (Evaluation method: except planimetric procedure) |

|---|

| ASTM E112 (Specimen adjustment: except heat treatment method) (Evaluation method: except planimetric procedure) |

B2.1.4

Microscopic test for the non-metallic inclusion

| JIS G 0555 |

|---|

| ASTM E45 method A, method D |

B2.2.2

Determination of decarbuized depth

| JIS B 1051(9.10.2) Microscopic Method |

|---|

For more detail, please go to the website of The Japan Accreditation Board for Conformity Assessment (JAB) .

Through JIS Q 17025, each laboratory is accredited as competent to undertake specific tests or calibrations within its scope of accreditation. ISO/IEC 17025 accreditation is mandatory for Nadcap material testing laboratory accreditation.

JIS Q 17025(ISO/IEC 17025)【Calibration Laboratory】

As a calibration laboratory, we are granted accreditation to JIS Q17025 Calibration Laboratories by Japan Accreditation Board for force calibration of testing machines.

The scope of accreditation:

– Uniaxial testing machine

– Tension & compression uniaxial testing machine

– Lever type tension uniaxial testing machine

| Certification Body: | Japan Accreditation Board(JAB) |

|---|---|

| Accreditation No. | RCL00490 |

| Range of Calibration | Expanded Uncertainty |

Reference Standard |

|---|

M14.6

Force

| – |

|---|

M14.6.1

Uniaxial testing machine(force)

Tension & compression uniaxial testing machine(tension only)

| From 1 kN up tp 100 kN |

0.27% | Class 1 (JIS/ISO) |

|---|

M14.6.1

Uniaxial testing machine(force)

Tension & compression uniaxial testing machine(tension only

| From 1 kN up tp 100 kN |

0.41% | Class A (ASTM) |

|---|

M14.6.1

Uniaxial testing machine(force)

Lever type tension uniaxial testing machine

| From 0.5 kN up tp 30 kN |

0.21% | Class 1 (ISO) |

|---|

M14.6.1

Uniaxial testing machine(force)

Lever type tension uniaxial testing machine

| From 0.5 kN up tp 30 kN |

0.24% | Class A (ASTM) |

|---|

JIS Q 17043(ISO/IEC 17043) 【Mechanical testing; Chemical testing】

JIS Q 17043 is a Japan Industrial Standard created without changing the technical content and structure of ISO / IEC 17043. Accreditation bodies grant accreditation to this standard to proficiency testing providers that satisfy the requirements.

The proficiency test provider accreditation is one of the means to determine the competence of a proficiency test provider providing specific types of proficiency testing. Customers can use this official approval as a convenient means to identify and select a reliable proficiency testing provider that satisfies their needs.

KMTL Edge Tech Co., Ltd, a group company of Kobe Material Testing Laboratory Co., Ltd. has been accredited to JIS Q 17043 since February, 2016. The accreditation scope was expanded on February 26, 2018,for the second time to perform proficiency testing for the following.

| Accreditation Body | Japan Accreditation Board(JAB) |

|---|---|

| Accreditation No. | PTP00040 |

M25

Mechanical testing

| – |

|---|

M25.A1

Metal materials, Fasteners and screw threads

| – |

|---|

M25.A1.1

Iron and Steel/Non-ferrous Metal

| – |

|---|

M25.A1.2

Fasteners and screw threads

| – |

|---|

M25.B13

Strength testing

| – |

|---|

M25.B13.1

Tensile strength & elongation testing

| JIS Z 2241 |

|---|

| JIS B 1051 9.1, 9.2 |

M25.B13.6

Hardness testing

| JIS Z 2245 |

|---|

| JIS B 1051 9.9 |

M26

Chemical testing

| – |

|---|

M26.1

Metal, Material of metal, Metal Products

| Refer to Appendix of Accreditation Certificate (Page 2/2) for elements and standards. |

|---|

M26.17

Environment Sample

| Refer to Appendix of Accreditation Certificate (Page 2/2) for elements and standards. |

|---|

For detail please access the website of Japan Accreditation Board (JAB). Japan Accreditation Board (JAB).

Nadcap

Nadcap is a global cooperative accreditation program for special processes* for aerospace engineering, defense and related industries administrated by the Performance Review Institute (PRI). Nadcap’s membership consists of “Prime Contractors” including Boeing, Airbus, GE, and Rolls Royce. Nadcap accreditation is mandatory for their suppliers.

* A special processes refers to the process where the product as a result of the process cannot be readily or economically inspected.

| Accreditation scope for Harima Workshop(47-13 Niijima, Harima-cho, Kako-gun, Hyogo 675-0155) |

|---|

| Accreditation body: PRI(Performance Review Institute) |

【 Materials Testing 】

In addition to our accreditation to ISO 17025 as an independent laboratory since 1999, we became the first material testing laboratory in Japan to be accredited by Nadcap in 2006. Since then, we have been updating and expanding our Nadcap accreditation scope.

■code

■Test Type

| ■Major Applicable Standards |

|---|

A

Room Temperature Tensile

| ASTM E8/E8M |

|---|

B

Elevated Temperature Tensile

| ASTM E21 |

|---|

C

Stress Rupture (Smooth)

| ASTM E139 |

|---|

XA

Creep

| ASTM E139 |

|---|

P

Fracture Toughness

| ASTM E399 |

|---|

O

High Cycle Fatigue

| ASTM E466 |

|---|

Y

Low Cycle Fatigue

| ASTM E606 |

|---|

XE

Crack Propagation Measurement

| ASTM E647 |

|---|

L0

Metallographic Evaluation

| ASTM E3、 ASTM E340 |

|---|

L1

Microindentation (Interior)

| ASTM E384 |

|---|

L11

Grain Size

| ASTM E112 |

|---|

L12

Inclusion Rating

| ASTM E45 |

|---|

L7

Near Surface Examinations – IGA, IGO

| ASTM E3 |

|---|

XL

Macro Examination

| ASTM E340 |

|---|

M1

Brinell Hardness

| ASTM E10 |

|---|

M2

Rockwell Hardness

| ASTM E18 |

|---|

M3

Vickers Hardness

| ASTM E92 |

|---|

Z

Standard Specimen Machining

| AC 7101/7 |

|---|

Z1

Low Stress Grinding

| AC 7101/7 |

|---|

Z2

Low Stress Grinding and Polishing

| AC 7101/7 |

|---|

【 Non Metallic Materials Testing 】

In August, 2017, we became the first laboratory in Japan to be accredited to Nadcap Non Metallic Materials Testing (NMMT) – Mechanical Testing.

Class A : Composites

■code

■Test Type

| ■Major Applicable Standards |

|---|

1.1.1

Tensile Ambient Temperature

| ASTM D3039/D3039M、 ASTM D5766/5766M |

|---|

1.1.2

Tensile Non-ambient Temperature

| ASTM D3039/D3039M、 ASTM D5766/5766M |

|---|

1.1.3

Tensile Strain Measurement

| ASTM D3039 |

|---|

1.2.1

Compression Ambient Temperature

| ASTM D6641/D6641M、 SACMA SRM1、 ASTMD6484/D6484M |

|---|

1.2.2

Compression Non-ambient Temperature

| ASTM D6641/D6641M、 SACMA SRM1、 ASTMD6484/D6484M |

|---|

1.2.3

Compression Strain Measurement

| ASTM D6641/D6641M、 SACMA SRM1 |

|---|

1.3.1

Shear Ambient Temperature by SBS

| ASTM D2344/D2344M |

|---|

1.3.2

Shear Ambient Temperature(±45Tension)

| ASTM D3518/D3518M |

|---|

1.3.4

Shear Ambient Temperature by V Notch

| ASTM D5379/D5379M |

|---|

1.3.5

Shear Non-ambient(any method)

| ASTM D2344、 ASTM D3518 |

|---|

1.3.6

Shear Strain Measurement

| ASTM D3518/D3518M |

|---|

1.18.1

G1c

| ASTM D5528 |

|---|

2.2.1

Density/ Specific Gravity

| ASTM D792 |

|---|

F.2.1

Specimen Fabrication

| AC7122-I |

|---|

F.3.1

Specimen Machining

| AC7122-I |

|---|

【Related links】PRI(Performance Review Institute) / SAE(Society of Automotive Engineers)

GE Aviation 【Special Process】-Specification S-400

GE-S-400 is the sourcing quality specification of GE Aviation for material testing laboratories. GE has accredited KMTL as a GE S-400 laboratory. The approved scope is as follows.

| Supplier code | T4274 |

|---|

■S-400 code

| ■Test type |

|---|

AI0A

| Room temperature tensile |

|---|

AI0B

| Elevated temperature tensile |

|---|

AI0C

| Stress rupture |

|---|

AI0L

| Metallography (Micro) |

|---|

AI0M

| Hardness |

|---|

AI0N

| Charpy Test |

|---|

AI0O

| High cycle fatigue (HCF) |

|---|

AI0P

| Fracture Toughness Determination |

|---|

AI0Y

| Low cycle fatigue (LCF) |

|---|

AI0Z

| Low stress grinding of test specimens |

|---|

AIXA

| Creep |

|---|

AIXE

| Crack Propagation Measurement |

|---|

AIXL

| Macro Metallography |

|---|

AIXR

| Residual Life |

|---|

AIXZ

| E50TF133 Grain Size Evaluation |

|---|

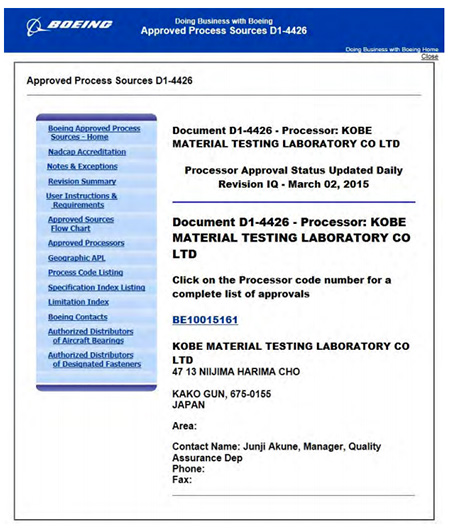

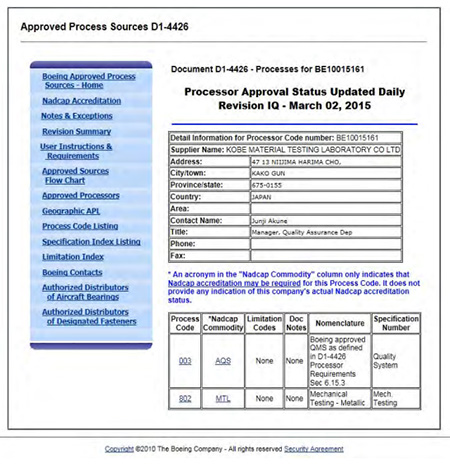

Boeing Approved Process Sources D1-4426 (MTL)

Boeing Approved Process Sources D1-4426 specifies Boeing requirements for its suppliers. Boeing has approved KMTL as a Boeing processor conforming to D1-4426 for material testing.

| Applicable Specification | D1-4426 |

|---|---|

| Scope of Approval | Mechanical Testing – Metallic |

| Processor Code number | BE10015161 |

Rolls-Royce Approved Supplier

KMTL has been confirmed to meet the requirements of Rolls-Royce Plc, and certified as an approved supplier of Rolls-Royce Plc.

| Vendor Number | 241161 |

|---|---|

| Scope of Approval | ・Test Piece Machining ・Mechanical testing(MSRR9922) |

Pratt & Whitney Approved Commercial Laboratory

KMTL has been confirmed to meet the requirements of Pratt & Whitney and approved as a P&W qualifiedapproved commercial laboratory. The approved test codes are as follows:

■Test code

| ■Test type |

|---|

1

| Tensile, Room Temperature |

|---|

3

| Stress Rapture |

|---|

7-a

| ME – Microstructure / Grainsize |

|---|

7-d

| ME – Braze |

|---|

7-e

| ME – Weld |

|---|

7-f

| ME – Nonconventional Machining,(LBMR) |

|---|

7-h

| ME- Heat Treat |

|---|

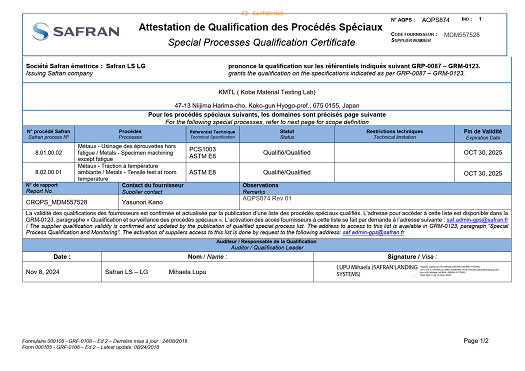

Safran Landing Systems Approved Supplier

KMTL has been confirmed to meet the requirements of Safran Landing Systems and is approved as a qualified commercial laboratory. The approved test codes are as follows:

| Applicable Specification | Special Processes Qualification |

|---|---|

| Scope of Approval | ・Test Piece Machining(Excluding fatigue testing) ※Applicable drawings are limited to PCS1003, 100028952, 100028954, 100028955. ・Room Temperature Tensile(ASTM E8) |

| Supplier No. | MDM557528 |

IHI Corporation

| Applicable Specification | ISAJT-F002, J-ISAJT-F002 |

|---|---|

| Name of Process | Non-Metallic Materials Testing |

Mechanical Test

■code *1

■Test Item

| ■Typical Reference Standard |

|---|

A(R,E,C)

Tensile Test (Room, Elevated, Cold Temperature)

| ASTM D3039/D3039M |

|---|

B(R,E,C)

In-Plane Shear Test (Room, Elevated, Cold Temperature)

| ASTM D3518/D3518M |

|---|

C(R,E,C)

Compressive Test (Room, Elevated, Cold Temperature)

| SACMA SRM1 |

|---|

D(R,E,C)

Compressive Test (Room, Elevated, Cold Temperature)

| ASTM D6641/D6641M |

|---|

E(R,E,C)

Short-Beam Strength Test (Room, Elevated, Cold Temperature)

| ASTM D2344/D2344M |

|---|

N(R,E,C)

Curved Beam Test (Room, Elevated, Cold Temperature)

| ASTM D6415/D6415M |

|---|

*1 Code (R,E,C) indicates test conditions; R: Room, E: Elevated, and C: Cold temperature.

Physical / Chemical / Thermal / Analytical Test

■Code

■Test Item

| ■Typical Reference Standard |

|---|

2A

Constituent Content of Composite

| ASTM D3171 |

|---|

2B

Density and Specific Gravity

| ASTM D792 |

|---|

| ASTM D1505 |

| ASTM D297 |

Specimen Fabrication

■Code

■Test Item

| ■Typical Reference Standard |

|---|

3B

PMC specimen fabrication (without tab)

| ISAJT-F004 Class-B |

|---|

| Applicable Specification | ISAJT-F005, J-ISAJT-F005 |

|---|---|

| Name of Process | Metallic Materials Testing |

Harima Workshop

■Code

■Test Item

| ■Typical Applied Standard |

|---|

A

Room Temperature Tensile

| ASTM E8/E8M and/or B557 |

|---|

B

Elevated Temperature Tensile

| ASTM E21 |

|---|

C

Stress Rupture

| ASTM E21(Smooth) |

|---|

| and/or E292 (Notched) |

XA

Creep Rupture

| ASTM E139 |

|---|

O

Force Controlled Fatigue

| ASTM E466 |

|---|

Y

Strain-Controlled Fatigue

| ASTM E606 |

|---|

P

Fracture Toughness

| ASTM E399 |

|---|

XE

Crack Propagation

| ASTM E647 |

|---|

L

Metallography

| ASTM E3 and/or E407 and/or E340 |

|---|

La

Grain Size

| ASTM E112 nd/or E930 and/or E1181 |

|---|

L1

Microhardness Interior

| ASTM E384 |

|---|

M1

Hardness – Brinell

| ASTM E10 |

|---|

M2

Hardness – Rockwell / Superficial

| ASTM E18 |

|---|

M3

Hardness – Vickers

| ASTM E92 |

|---|

Z

Specimens

| ISAJT-F001 |

|---|

Ibaraki Workshop

■Test Code

■Test Item

| ■Typical Applied Standard |

|---|

A

Room Temperature Tensile

| ASTM E8/E8M and/or B557 |

|---|

B

Elevated Temperature Tensile

| ASTM E21 |

|---|

O

Force Controlled Fatigue

| ASTM E466 |

|---|

Y

Strain-Controlled Fatigue

| ASTM E606 |

|---|

XE

Crack Propagation

| ASTM E647 |

|---|

Z

Low Stress Grinding of Test Specimens

| ISAJT-F001 |

|---|

| Applicable Specification | ISAJT-F009 |

|---|---|

| Name of Process | CMC and CMC Raw Materials Testing |

■Test Code

■Test Item

| ■Typical Reference Standard |

|---|

1J

In-plane Tension-Tension Cyclic Fatigue Test

| ASTM C1360 |

|---|

MITSUBISHI HEAVY INCUSTRIES, LTD.

| Applicable Specification | MSJ4000 |

|---|---|

| Applicable Basic Requirement | AS/EN/JIS Q 9100:2016 |

| Applicable Scope | Specimen preparation, testing, investigation, and report preparation on materials, parts, and products for aerospace industries |

| Exclusion from Application | 8.3 Design and Development of Products and Services |

| Applicable Specification | MS84001 SectionB |

|---|---|

| Applicable Scope | Manufacturing |

| Applicable Product | Subcontract of specimen preparation and tensile testing only |

| Limiting Condition | Limited to tensile testing of SM-3 nose cone shroud |

Kawasaki Heavy Industries, Ltd. Aerospace Systems Company

| Applicable Specification | KQ-7204 |

|---|---|

| Name of Process | Material Testing |

Harima Workshop

■Test Code

■Testing

| ■Applicable Test Standards |

|---|

1

Room Temperature Tensile

| ASTM E8、ASTM B557、JIS Z2241 |

|---|

2

Elevated Temperature Tensile

| ASTM E21、JIS G0567 |

|---|

3

Stress Rupture

| ASTM E139、ASTM E292、JIS Z2271 |

|---|

4

Creep, Creep Rupture

| ASTM E139、JIS Z2271 |

|---|

5

Fatigue-Load Controlled

| ASTM E466 |

|---|

6

Fatigue-Strain Controlled

| ASTM E606 |

|---|

7

Fatigue Crack Propagation

| ASTM E647、ISO 12108 |

|---|

9

Impact

| ASTM E23、 JIS Z2242 |

|---|

11

Bending

| ISO 7438、JIS Z2248 |

|---|

20

Brinell

| ASTM E10、JIS Z2243 |

|---|

21

Rockwell

| ASTM E18、JIS Z2245 |

|---|

22

Vickers

| ASTM E92、JIS Z2244 |

|---|

23

Microindentation

| ASTM E92、ASTM E384 |

|---|

30

General Microstructure

| ASTM E3、ASTM407 |

|---|

30-a

Grain Size

| ASTM E112、ASTM E930 |

|---|

30-e

Abusive Machining

| ― |

|---|

30-f

Nonconventional Machining

| ― |

|---|

31

Macrostructure

| ASTM E340 |

|---|

Wege crack Propagation (JAEC-J-MCL-S-100)

| Applicable Specification | J-ISAJT-F002 |

|---|---|

| Name of Process | Non Metallic Materials Testing Laboratories |

| Applicable Specification | J-ISAJT-F005 |

|---|---|

| Name of Process | Metallic Materials Testing Laboratories |

Harima Workshop

■Code

■Test Item

| ■Typical Applied Standard |

|---|

A

Room Temperature Tensile

| ASTM E8/E8M、ASTM B557 |

|---|

B

Elevated Temperature Tensile

| ASTM E21 |

|---|

C

Stress Rupture

| ASTM E139 (Smooth) |

|---|

| ASTM E292 (Notched) |

XA

Creep Rupture

| ASTM E139 |

|---|

O

Force Controlled Fatigue

| ASTM E466 |

|---|

Y

Strain-Controlled Fatigue

| ASTM E606 |

|---|

P

Fracture toughness

| ASTM E399 |

|---|

XE

Crack Propagation

| ASTM E647 |

|---|

L

Metallography

| ASTM E3、ASTM E407、ASTM E340 |

|---|

La

Grain size

| ASTM E112、ASTM E930、ASTM E1181 |

|---|

L10

Conventional machining

| *1 |

|---|

L13

Other

| *1 |

|---|

M1

Hardness – Brinell

| ASTM E10 |

|---|

M2

Hardness-Rockwell / Superficial

| ASTM E18 |

|---|

M3

Hardness-Vickers

| ASTM E92 |

|---|

Z

Low Stress Grinding of Test Specimens

| ISAJT-F001 |

|---|

F2

ICP

| JIS H1307、JIS H1352 |

|---|

*1:Each drawing requirements or specifications called from each drawing

| Applicable Specification | ISAJT-F005 |

|---|---|

| Name of Process | Metallic Materials Testing |

Harima Workshop

■Code

■Test Item

| ■Typical Applied Standard |

|---|

L11

Non-conventional machining

| Each drawing requirements or specifications called from each drawing. |

|---|

Kobe Steel, Ltd.

■Test

| ■Applicable Standard |

|---|

Elevated Temperature Tensile Testing

| ASTM E21 |

|---|

Room Temperature Rupture Testing

| ASTM E139、ASTM E292 |

|---|

Room/Elevated Temperature Creep Rupture Testing

| ASTM E139、ASTM E292 |

|---|

- 1947

- Founded as a test-piece manufacturing factory.

- 1967

- Started contracted material testing as the first private laboratory in Japan.

- 1979

- Opened a laboratory at Niijima, Harima-cho, Kako-gun, Hyogo-pref.

- 1985

- Started chemical business.

- 1986

- Started machine tool and equipment manufacturing business.

- 1996

- Certified to ISO 9002 Quality Systems.

- 1998

- Accredited to ISO/IEC 17025 (ISO Guide 25)Testing Laboratory Accreditation: Mechanical Testing(JAB).

- 1999

- Accredited to ISO/IEC 17025(JNLA).

- 2001

- Expanded ISO/IEC 17025 accreditation scope: Polymer materials(JNLA).

- 2002

- Transferred to ISO 9001:2000.

Obtained Medical Device Manufacturing Approval.

- Transferred to ISO 9001:2000.

- 2005

- Certified to JIS Q 9100.

- 2006

- Accredited to Nadcap MTL (Metallic Materials).

Transferred to ISO/IEC 17025:2005 with expanded accreditation scope.

- Accredited to Nadcap MTL (Metallic Materials).

- 2007

- Obtained No. 1 Type License for Marketing Business of Medical Devices.

- 2008

- Expanded Nadcap MTL accreditation scope.

Expanded ISO/IEC 17025 accreditation scope: Chemical testing

- Expanded Nadcap MTL accreditation scope.

- 2009

- Approved to GE S-400.

Ibaraki Workshop accredited to ISO/IEC 17025: Mechanical Testing.

- Approved to GE S-400.

- 2010

- Expanded ISO/IEC 17025 accreditation scope:EN standard.

Transferred to ISO 9001:2008.

- Expanded ISO/IEC 17025 accreditation scope:EN standard.

- 2011

- Tsurui Chemical Co., Ltd. certified to ISO 9001.

- 2012

- Updated approval to GE S-400.

- 2015

- Approved to Boeing Approved Process Sources D1-4426 (Mechanical Testing – Metallic).

Approved by Rolls Royce.

- Approved to Boeing Approved Process Sources D1-4426 (Mechanical Testing – Metallic).

- 2017

- Accredited to Nadcap NMMT (Non Metallic Materials Testing): Mechanical Testing.

- 2019

- Approved by Pratt & Whitney.

.jpg)