-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

OTHER SERVICE

DEVICE DEVELOP

Equipment Development

In safety design of structures, their load conditions and fracture behavior must be sufficiently grasped. For this purpose, testing that simulates the actual load conditions, atmosphere and environment is required. KMTL designs and manufactures special testing and other machines based on the precision machining and advanced testing technologies developed over a long period of years.

Special Test Equipment

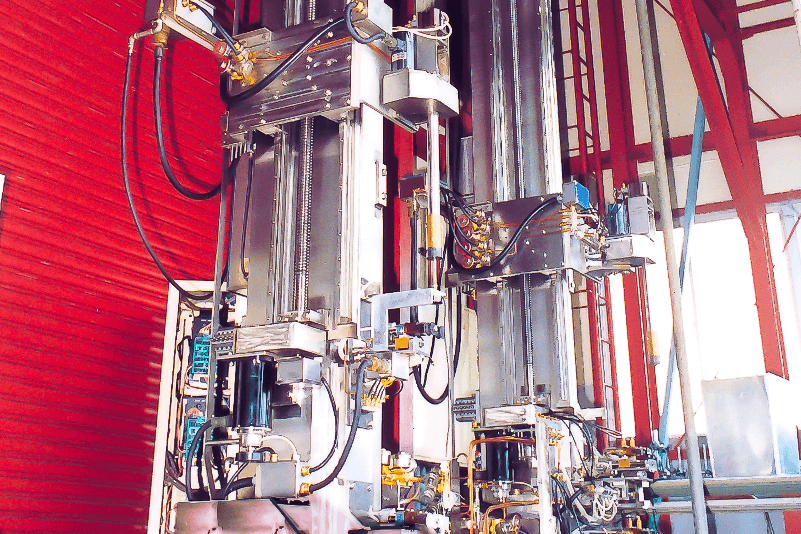

Biaxial creep testing machine

Biaxial creep test specimen

Creep fatigue interaction testing machine(FCI)

Positioning and transfer equipment for measurements and observation of nuclear fuel rods

Main developments

| High-temperature and high-pressure circulation type corrosion testing equipment | Rotational corrosive-wear testing equipment |

|---|---|

| Octuple fretting-wear testing machine | Miniature creep testing machine |

| Dynamic 4-point bending plastics testing machine | High-speed tensile testing machine with thermostatic oven |

| Automatic Charpy-specimen mounting equipment | Creep testing machine for plastics |

| Rolling fatigue contact testing machine |

| Motoring testing machine | Differential endurance testing machine |

|---|---|

| V-belt slip fatigue testing machine | Oil-pump endurance testing machine |

| Dynamic 4-point bending plastics testing machine | Crankshaft fatigue testing machine |

| Fuel rod welding equipment | Precracking equipment for hot cells |

|---|---|

| Remote automation tensile specimen machining equipment for hot cells | Specimen injection molding machine for hot cells |

| Electric discharge machining equipment for hot cells |

| Boiler header inner surface inspecting equipment | Boiler main stream pipe inner surface inspecting robot |

|---|---|

| Miniature specimen longitudinal polishing equipment (Φ1) | High-temperature hign-pressure heat treating equipment |

Electric discharge sampling equipment

This equipment has been developed to accurately evaluate the residual life or investigate the failure of large plant-components with a minimized amount of samples taken. (Standard sample size: 2.5 (t) x 20 (w) x 40 (l) mm) Various types of testing are available using the extracted samples, featuring destructive testing on our self-developed miniature series testing machines including miniature tensile, high-cycle/low-cycle fatigue, and creep testing machines.

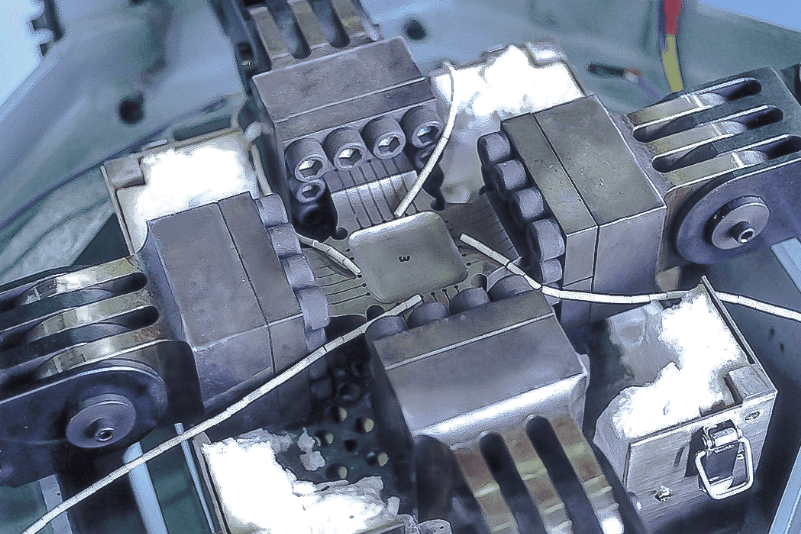

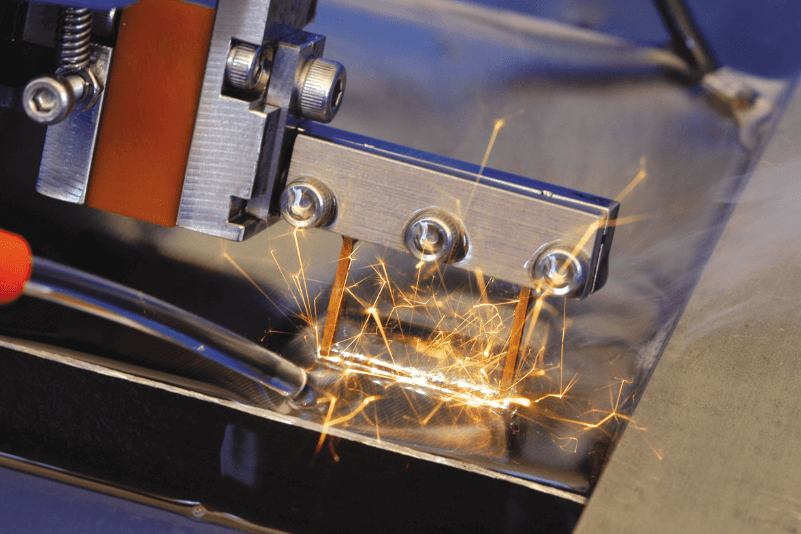

Electric Discharge sampling equipment

Enlarged view of electric discharge sampling

| Portable to be used for on-site sampling. |

| Minimizing effect of sampling by scooping the surface of the object. |

| Selectable sampling position to suit the object shape. |

| Preventing machining and thermal deformation. |

| Reduced sampling cost |

Miniature fatigue testing machine

This equipment has been developed for residual life evaluation of high-temperature components of power plants. It uses a miniature size specimen (2 mm thick) that minimize the effect to the component, enabling to secure the component strength and reliability by minimizing the damage given. Using this equipment will bring about sophisticated maintenance operation and reduce the maintenance cost and period.

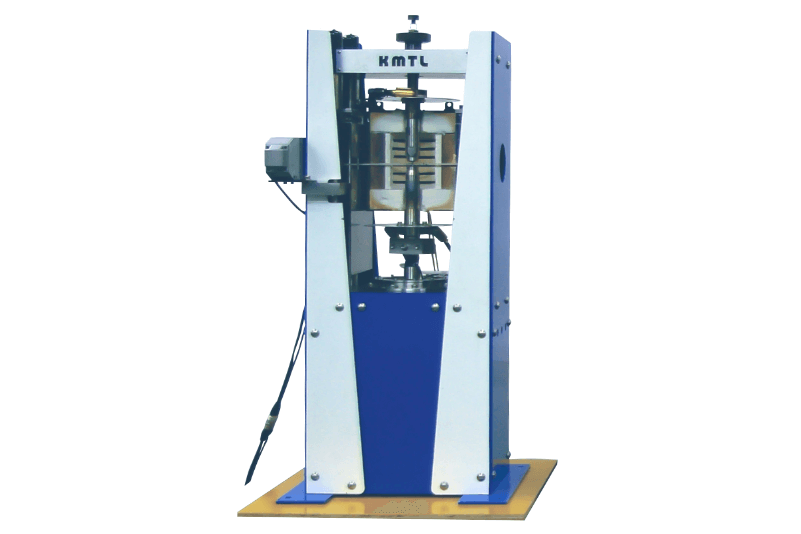

Miniature fatigue testing machine

| Low cycle fatigue testing is available with a gage diameter of 1.5 mm. |

| Testing is available with a 3-mm thick sheet. |

| Axial strain contoll between gage marks is available. |

| Excessive load during specimen setting and heating can be prevented. |

Creep testing machine

Creep testing to JIS, ASTM and other standards are mandatory for aerospace, power generation, auto, and high-temperature and high-pressure components. The creep testing machine we offer is of high accuracy and meets required international standards, satisfying each customer’s needs.

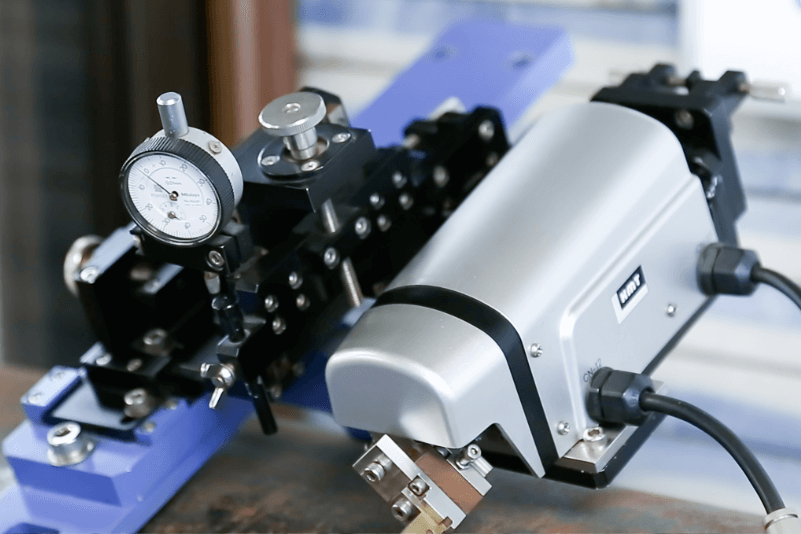

Creep testing machines

Temperature controller

| Customized design is available, e.g. space saving. |

| Recovery in case of sudden power outage (Heater automatically resumes after the pre-set time of power outage.) |

| Customized testing fixtures to fit specimen size variation (optional) |

| Repair, maintenance, load calibration, and design alteration service |

TEST SERVICE

Other Service

KMTL also support the production of test pieces and varhttps://en.kmtl.co.jp/wp-admin/users.phpious equipment required for testing and analysis and provide total support for material testing.

Test Specimen Preparation

Sophisticated Machining Skills

Sampling and Machining Miniture Test Specimens