-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

OTHER SERVICE

DEVICE DEVELOP

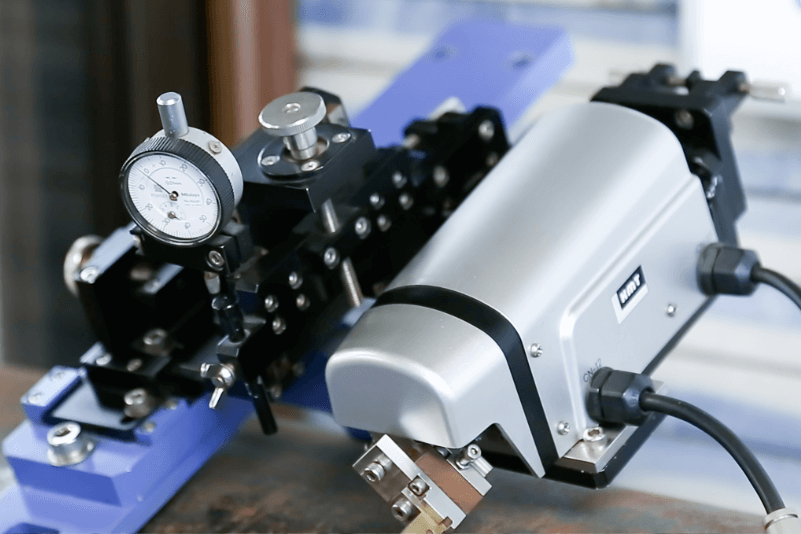

Electric Discharge Sampling Equipment

This equipment has been developed to accurately evaluate the residual life or investigate the failure of large plant-components with a minimized amount of samples taken. (Standard sample size: 2.5 (t) x 20 (w) x 40 (l) mm) Various types of testing are available using the extracted samples, featuring destructive testing on our self-developed miniature series testing machines including miniature tensile, high-cycle/low-cycle fatigue, and creep testing machines.

Electric Discharge sampling equipment

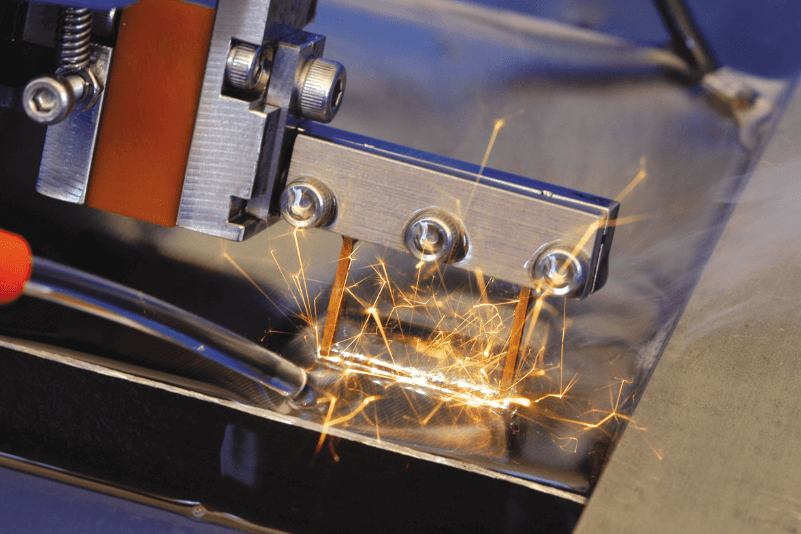

Enlarged view of electric discharge sampling

| 1. Portable to be used for on-site sampling. |

| 2. Minimizing effect of sampling by scooping the surface of the object. |

| 3. Selectable sampling position to suit the object shape. |

| 4. Preventing machining and thermal deformation. |

| 5. Reduced sampling cost |

DISCHARGE SAMPLING SYSTEM

ON-SITE SAMPLING USING EDSE

In all industries such as the electric power industry using thermal power generation, evaluating residual life and ensuring reliability and health of operating plants are important international issues. Our unique Electric Discharge Equipment (EDSE) aids in periodic maintenance and other inspections at the sites of the plants through sample extraction, as required by the customer, as well as in removal of the defective or deteriorated parts of components.

| ① uses Electric Discharge Sampling Equipment developed by our company, |

| ② takes samples directly from plant components (Sample thickness: 2.5 mm), |

| ③ shortens time required to extract a sample (Standard time for taking a sample: 2 – 3 hours), |

| ④ includes scaffolding and curing (Normal work period: 1 week), |

| ⑤ requires no big work, extracting a small sample, |

| ⑥ is available at low cost utilizing the equipment and excellent staff, |

| ⑦ can be conducted at any place for any part, and |

| ⑧ causes little adverse effect on facilities and components. |

Examples of past work

| Boiler Header Piping |

|---|

| Sampling location | Outer surface bottom and side |

|---|---|

| Extracted sample size | 3.5t × 20W × 56L |

| Processing liquid | Pure water |

| Electrode | Silver tungsten |

| Gas Turbine Rotor |

|---|

| Sampling location | Outer surface weld |

|---|---|

| Extracted sample size | 2.5t × 20W × 40L |

| Processing liquid | Oil |

| Electrode | Copper |

| Large Diameter Pipe |

|---|

| Sampling location | Inside |

|---|---|

| Extracted sample size | 4.0t × 20W × 65L |

| Processing liquid | Oil |

| Electrode | Copper |

| Spherical Tank |

|---|

| Sampling location | Inner slanted area |

|---|---|

| Extracted sample size | 10t × 20W × 60L |

| Processing liquid | Pure water |

| Electrode | Silver tungsten |

TEST SERVICE

Other Service

KMTL also support the production of test pieces and various equipment required for testing and analysis and provide total support for material testing.

Test Specimen Preparation

Sophisticated Machining Skills

Sampling and Machining Miniture Test Specimens