-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

OTHER SERVICE

RF SERIES

RF Series

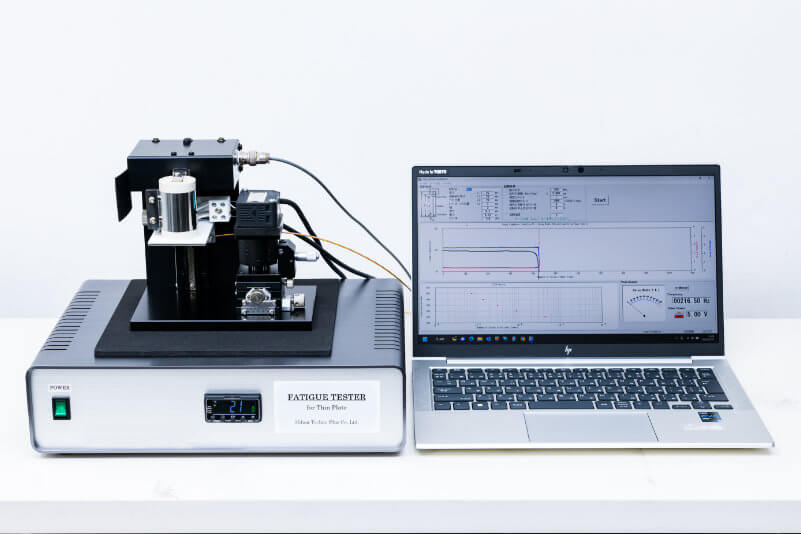

Resonance Fatigue Testing Device for Thin Plate and Wire

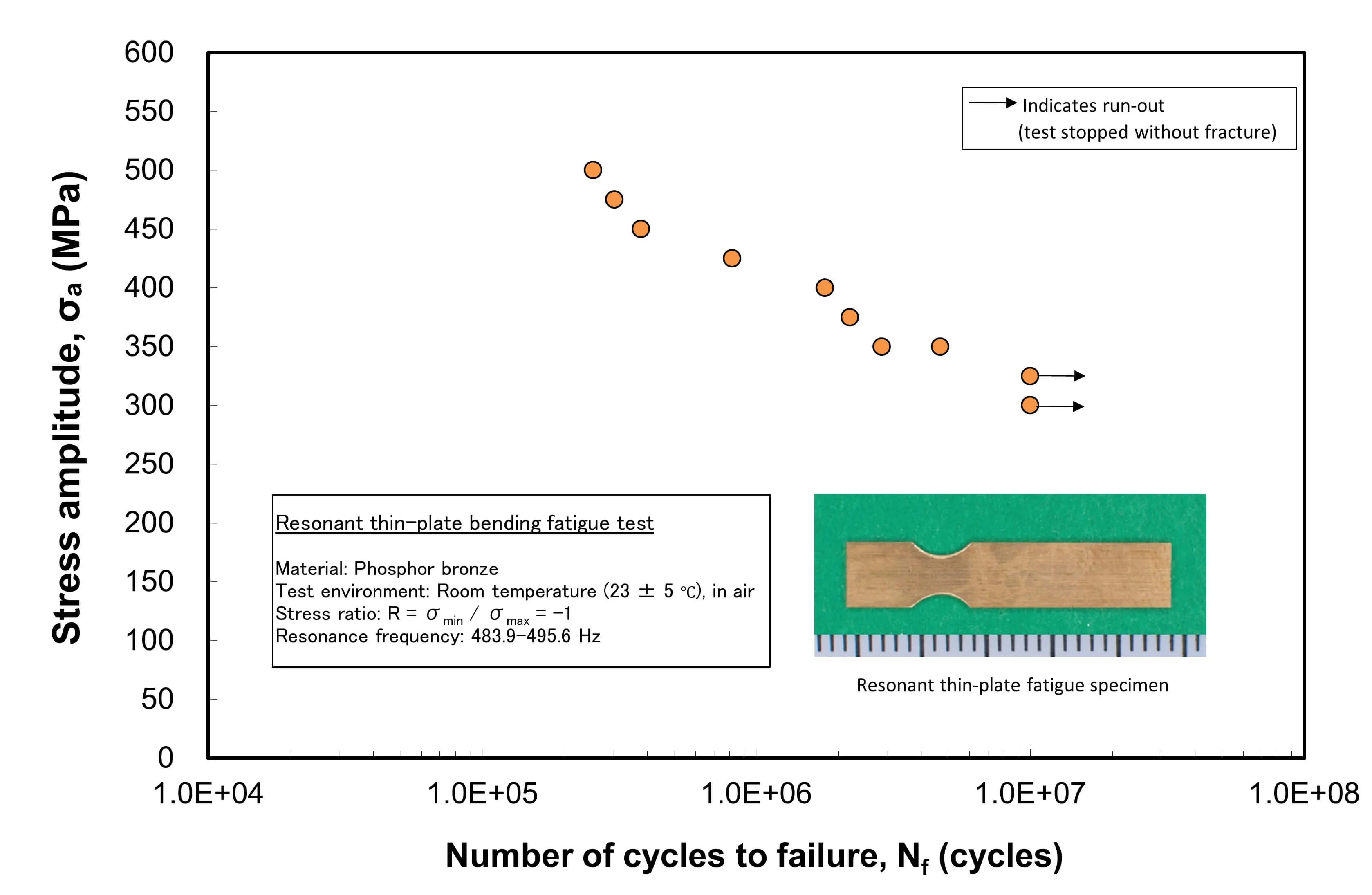

Resonance fatigue testing uses the principle of resonance to apply cyclic stress to a specimen. By measuring the number of cycles to failure at each stress amplitude, an S-N curve can be generated to characterize the material’s fatigue performance.

SN Diagram

Features of RF Series

The RF Series is a resonance-type fatigue testing device specialized for bending fatigue tests of thin plates. It is capable of performing fully reversed bending fatigue tests on specimens with a thickness of 0.8 mm or less, which is typically challenging with conventional mechanical plane-bending fatigue testers. The device can also be used as an alternative method for fully reversed axial fatigue testing on thin plates, though differences in loading mode should be considered.

RF-HT

RF-RT

The resonance frequency in fatigue testing depends on the specimen geometry and dimensions, and the material’s Young’s modulus and density. The RF Series supports fatigue tests over a frequency range of 100 to 1,000 Hz. Considering that conventional fatigue machines are typically limited to frequencies of several tens of Hz, the RF Series offers an advantage of evaluating fatigue properties in significantly reduced testing time. For example, a fatigue test of 10 million cycles at 500 Hz can be completed in only 5.5 hours, whereas the same test at 30 Hz on a conventional machine would take approximately 90 hours (around 4 days). Its high-frequency capability also enables ultra-high-cycle fatigue testing over 10 million cycles. By using the RF Series, product research and development can be accelerated.

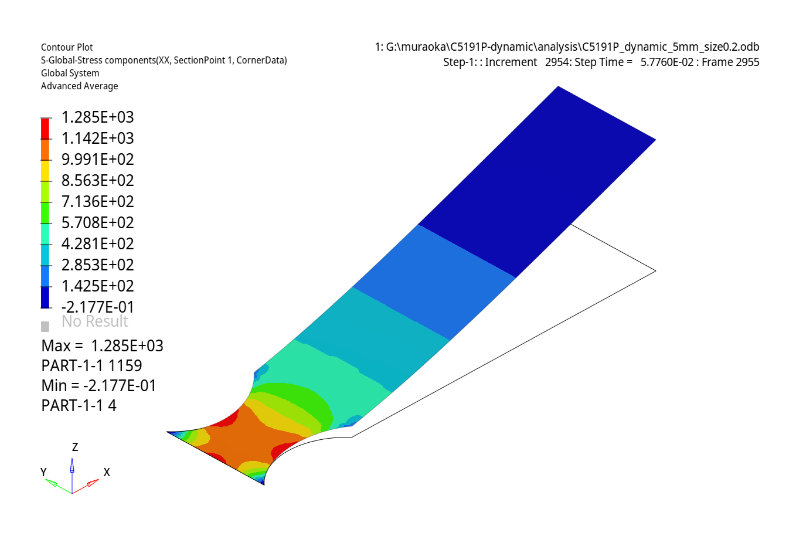

In the RF Series, a laser displacement sensor is used to control the displacement amplitude corresponding to a specified stress amplitude. Stress values are calculated using finite element method (FEM) analysis. Unlike plane bending machines, which apply forced displacement using an eccentric cam and calculate bending stress based on mechanics-of-materials solutions, the RF Series excites the entire specimen in resonance with one fixed end (cantilevered), thereby applying dynamic bending stress. Because the resulting dynamic bending stress does not agree with mechanics-of-materials-based solutions, FEM analysis is required. KMTL measured the displacement distribution of the specimen and confirmed that it agrees with the FEM analysis with high accuracy.

FEM Contour Diagram

KMTL provides a full range of services covering the design, analysis, machining, and fatigue testing of thin-plate specimens. The RF Series offers a unique testing capability not available with other machines, making it a valuable tool for material research and development and for the strength design of thin-plate products.

General Specifications of RF Series

| Capable of fully reversed bending fatigue testing on specimens with a thickness of 0.8 mm or less |

| Enables short-time fatigue testing (e.g., a fatigue test of 10 million cycles at 500 Hz can be completed and recorded in approximately 5.5 hours) |

| Displacement amplitude control (fully reversed loading, R = −1) |

| Cantilever resonance method |

| Decrease in resonance frequency |

| Electromagnetic excitation |

| High-precision laser displacement sensor; maximum displacement amplitude: ±5 mm |

| 100 Hz to 1,000 Hz |

| Metals, ceramics |

| Plate: Thickness 0.05–0.8 mm × Width 3–5 mm × Length 15–35 mm |

| Wire: Diameter 0.1–0.5 mm × Length 25–35 mm |

| RF-RT (Room temperature) |

| RF-HT(Room temperature to 200℃) |

| 350W×260D×300H (mm) |

※1Specifications and appearance are subject to change without notice due to product improvements.

※2The above specifications are standard; custom configurations are available upon request.