-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

NEWS

NEW TECH

NEWS

NEW TECH

Category

Archive by year

NEW TECH

Fatigue crack growth test method using Kb-Bar specimen has been established.

Many aircraft component failures originate from small surface flaw cracks in highly stressed locations. To evaluate aerospace materials, it is said to be desirable that fatigue crack growth characteristics be determined under the conditions of high-stress and small semicircular surface crack shape.

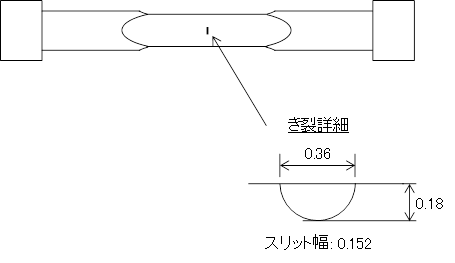

With such a background, aircraft manufacturers have adopted the fatigue crack growth test method using a Kb-bar specimen in material standards for aircraft engines. This test method uses a rectangular cross-section specimen with a small semi-elliptical notch precisely machined on the surface, and measures crack growth during the test using the electrical potential drop (EPD) method.

We would like to announce that our laboratory has established the fatigue crack growth test method using a Kb-Bar specimen, where test data including crack lengths during testing are measured automatically. We will continue to meet your needs for evaluating aircraft materials for the future.

Figure: Kb-Bar specimen configuration