-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

TEST SERVICE

HYDROGEN EMBRITTLEMENT TEST

Toward a Hydrogen Society: Innovation, Challenges,

and Future Prospects in the Energy Transition

Contents

- Mechanisms and Challenges of Hydrogen Embrittlement

- Challenge 1: Effects on Metallic Materials

- Challenge 2: Safety Management and Cost

- Solution: Strength Testing Using Hydrogen Gas-Sealed Hollow Specimens

- Continuous Electrochemical H-Charging for SSRT Test

- SSRT, Fatigue Life and Fatigue Crack Growth Tests

Under 100 MPa Class High Pressure Hydrogen Gas Environment - New Test Method for Small-Sized Specimens

under High-Pressure Gaseous Hydrogen - Test Procedure

- Testing Performance in High Pressure Hydrogen Gas Environment

- KMTL‘s Standard Specimen Designs

- Core Technology of KMTL’s Miniature Testing Method

- Measurement and Analysis of Hydrogen Diffusivity, D

Amid the global push toward a decarbonized society, hydrogen is emerging as a next-generation energy source. ‘Green hydrogen’, which emits no CO2 when combusted, is expected to be a key solution for reducing greenhouse gas emissions.

Hydrogen’s potential extends beyond climate change mitigation; it also enhances energy security. Developing domestic hydrogen production and utilization capabilities reduces dependence on fossil fuel imports and mitigates geopolitical risks. Hydrogen also functions as an ‘energy carrier’, absorbing fluctuations in renewable energy output and supporting a stable electricity supply. Furthermore, efforts are underway to produce hydrogen using the stable output of nuclear power. By combining diverse power sources, we can establish a stable hydrogen supply system.

Hydrogen is also set to transform the industrial sector. In particular, the steel industry is shifting to steelmaking processes that use hydrogen as a reducing agent, significantly contributing to the reduction of CO2 emissions. In the power sector, combustion technologies such as hydrogen gas turbines and hydrogen engines are being developed, enabling the use of existing facilities while reducing CO2 emissions.

To achieve widespread hydrogen adoption, advancements in transportation and storage technologies are essential. Because hydrogen has a low volumetric energy density at ambient temperature and pressure, its liquefaction—by cooling it to approximately 20 K (−253°C), which reduces its volume to about 1/800—is being explored as a means of efficient large-scale transportation. This enables large-scale, long-distance transport. In addition, efforts are underway to repurpose existing gas pipeline networks into hydrogen-dedicated pipelines, with the aim of establishing broad and stable hydrogen supply networks.

Nevertheless, significant challenges remain before the realization of a hydrogen-based society. Hydrogen can cause brittleness in some metallic materials, making it necessary to ensure the safety and durability of pipelines and storage tanks. Significant hurdles also remain in the form of high energy costs for liquefaction and compression, the development of related technologies, and the establishment of legal and regulatory frameworks.

At Kobe Material Testing Laboratory Co., Ltd., we believe hydrogen holds the potential to drive technological innovation and foster new industries across every stage—production, storage, transport, and use. We are actively engaged in developing advanced testing and evaluation technologies for materials in hydrogen environments. The following sections provide a basic overview of hydrogen embrittlement mechanisms along with our testing achievements and plans for technological development.

Mechanisms and Challenges of Hydrogen Embrittlement

The demand for using structural materials in hydrogen environments is increasing, but challenges remain.

Challenge 1: Strength Design and Hydrogen Embrittlement Evaluation

of Structural Materials

- Can existing designs be used as they are?

- Is fundamental improvement necessary?

One of the major concerns in strength design is hydrogen embrittlement — a phenomenon where hydrogen atoms penetrate and diffuse into metallic materials, potentially degrading their mechanical properties in various ways.

- Delayed Fracture Hydrogen accumulates in the material over time, eventually causing sudden fracture even under constant external stress. This is especially common in high-strength steels.

- Decrease in tensile properties, such as elongation at break and reduction of area Hydrogen exposure reduces ductility, resulting in lower elongation and area reduction — typical indicators of embrittlement.

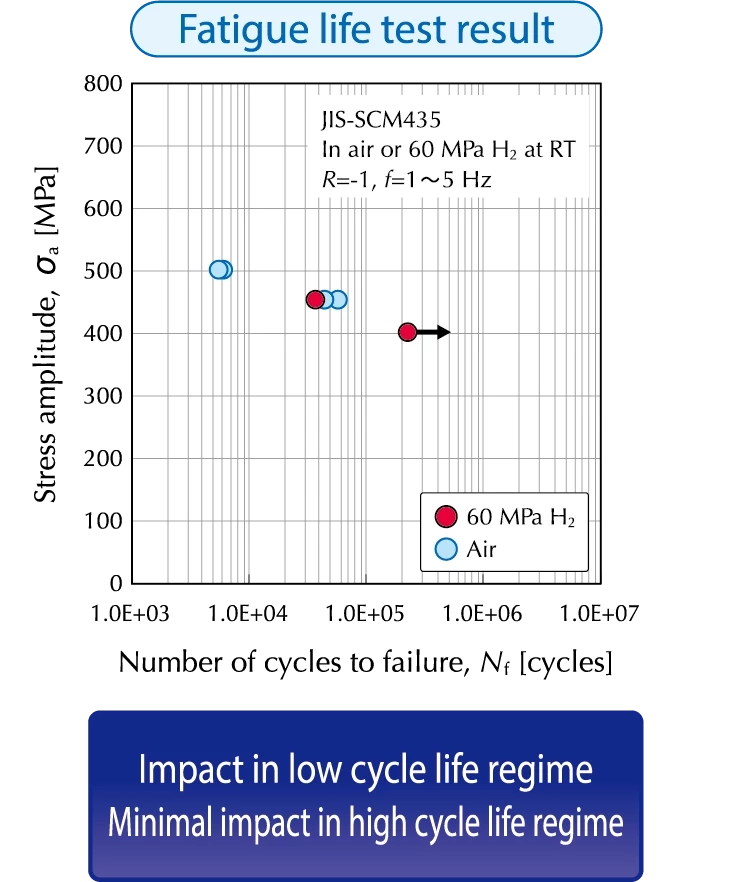

- Reduction in fatigue life and fatigue limit Repeated loading leads to failure in fewer cycles than normal, resulting in a shorter fatigue life. In some cases, the stress threshold below which fatigue failure does not occur (fatigue limit) also decreases—a factor that must be considered in design.

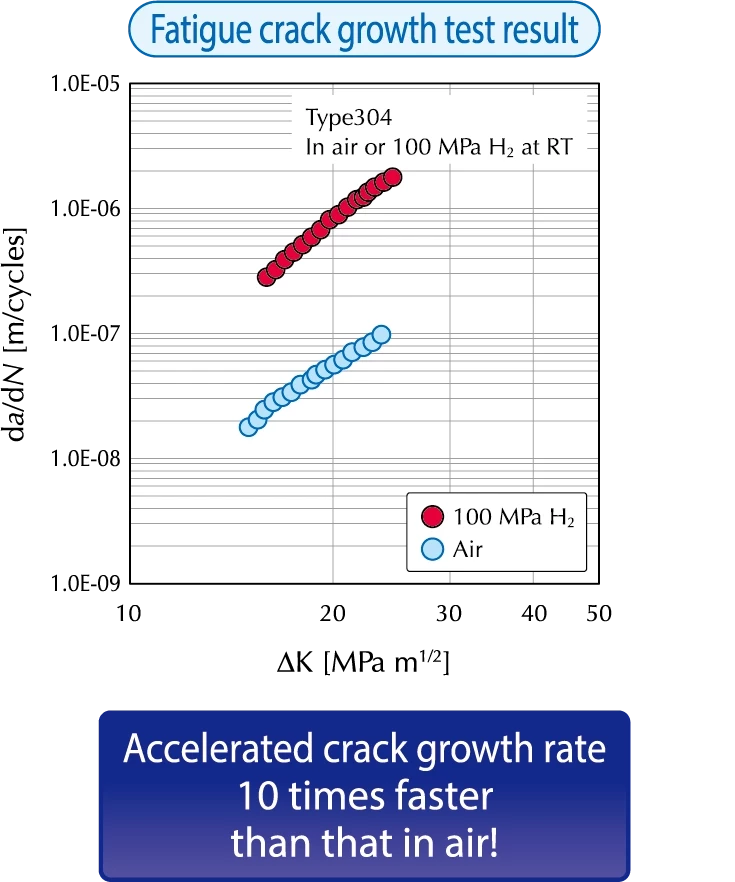

- Acceleration of Fatigue Crack Growth Rate Hydrogen accelerates the propagation of fatigue cracks, often by concentrating at crack tips and locally facilitating embrittlement of the material.

- Decrease in Fracture Toughness Hydrogen reduces a material’s ability to resist crack propagation (i.e., fracture toughness), increasing the likelihood of brittle fracture.

Challenge 2: Safety Management and Cost

To promote the use of hydrogen energy, challenges exist not only in evaluating material safety but also in conducting the tests themselves.

Challenges

- Hydrogen is highly flammable, requiring specialized handling knowledge and rigorous safety measures.

- Testing materials in hydrogen gas environments demands costly, explosion-proof setups.

- Contract testing services in hydrogen environments tends to be expensive, posing a barrier to the development of a hydrogen-based energy society.

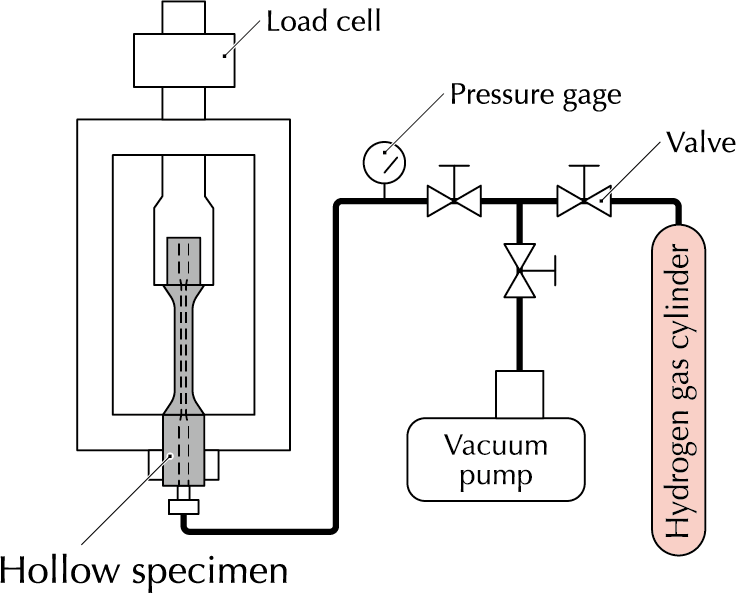

Solution: Strength Testing Using Hydrogen Gas-Sealed Hollow Specimens

Advantages:

- Enables strength testing while exposing the material’s surface to hydrogen gas

- Uses minimal amount of hydrogen gas, ensuring safety even if hydrogen gas diffuses outside the specimen.

- Integrates with KMTL’s core testing technologies,

➡ allowing us to meet diverse testing needs at reasonable cost.

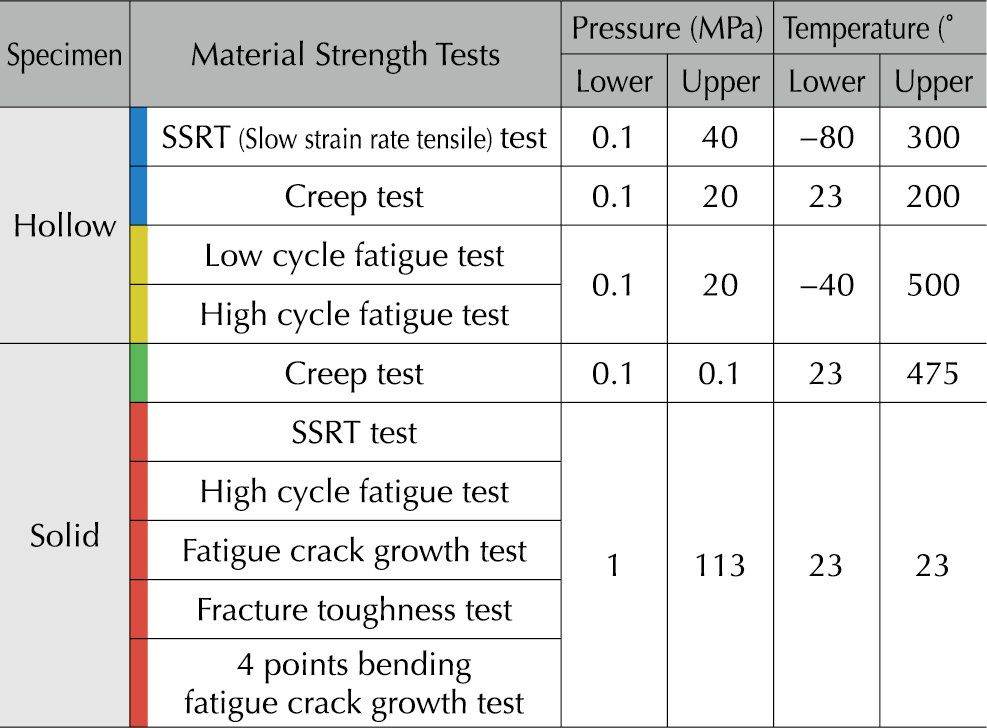

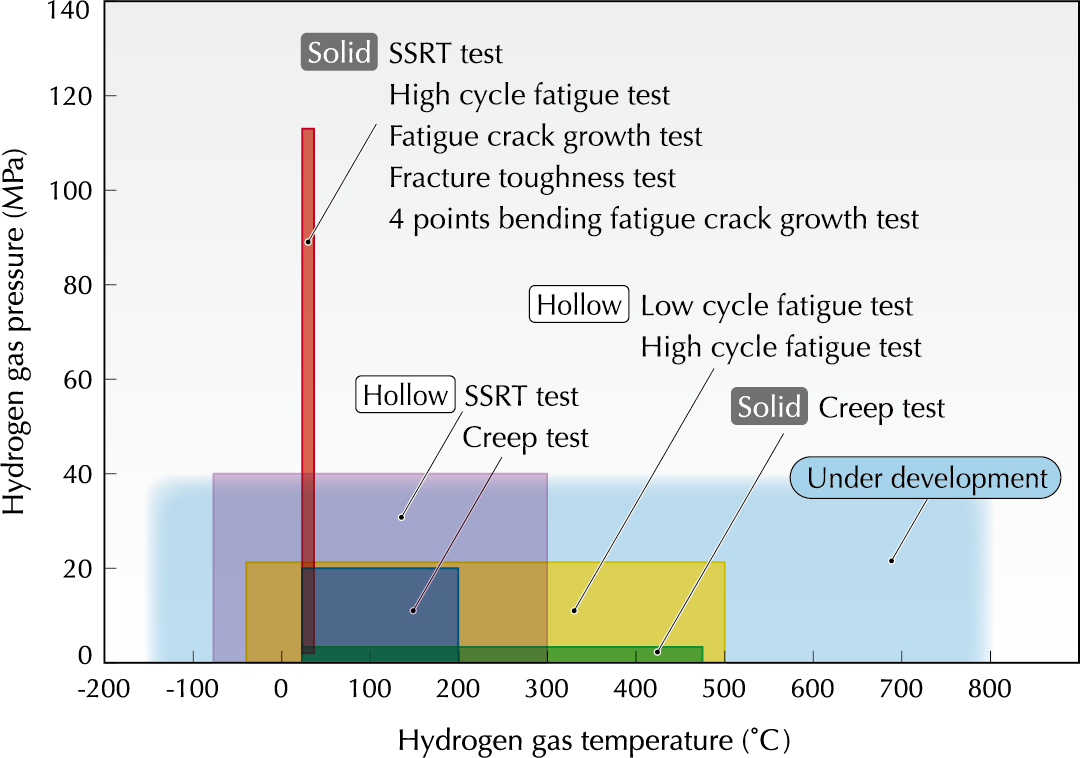

Hydrogen Material Test Conditions and Scope at KMTL

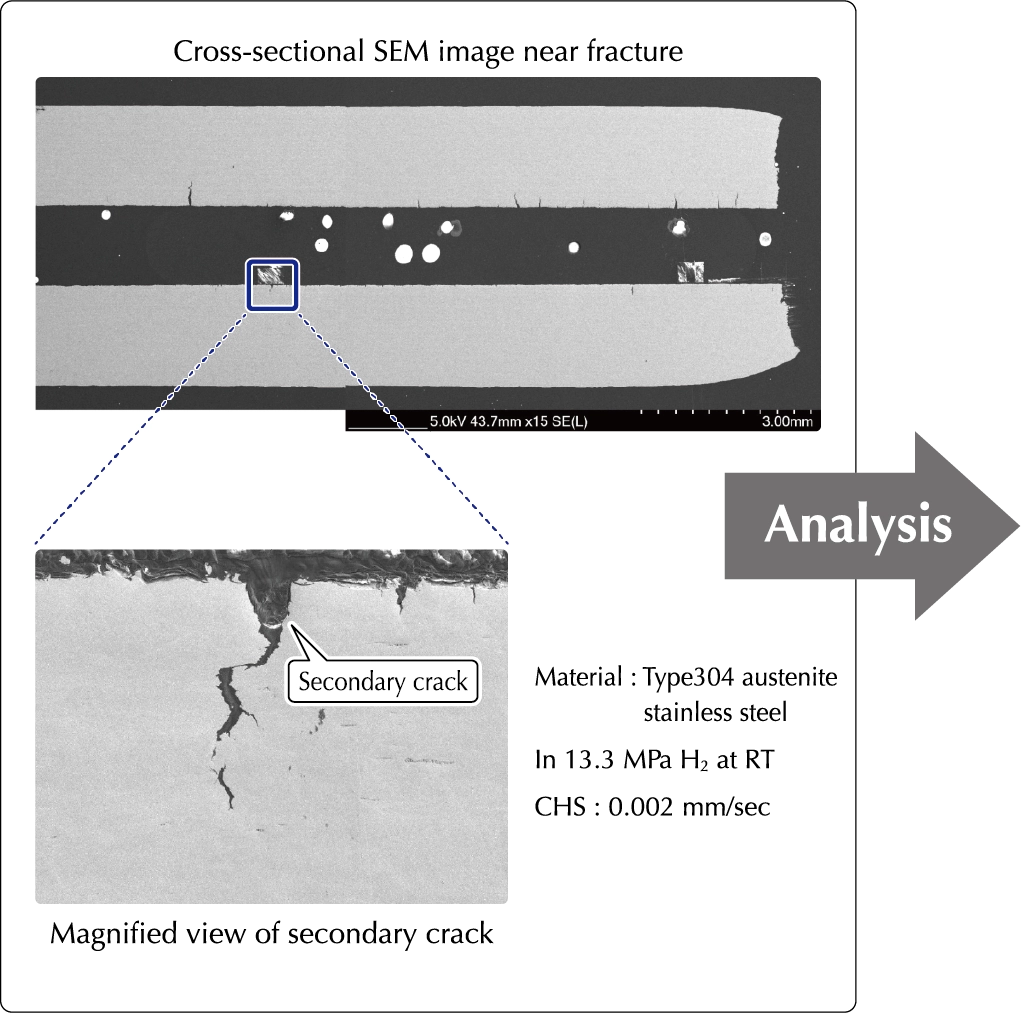

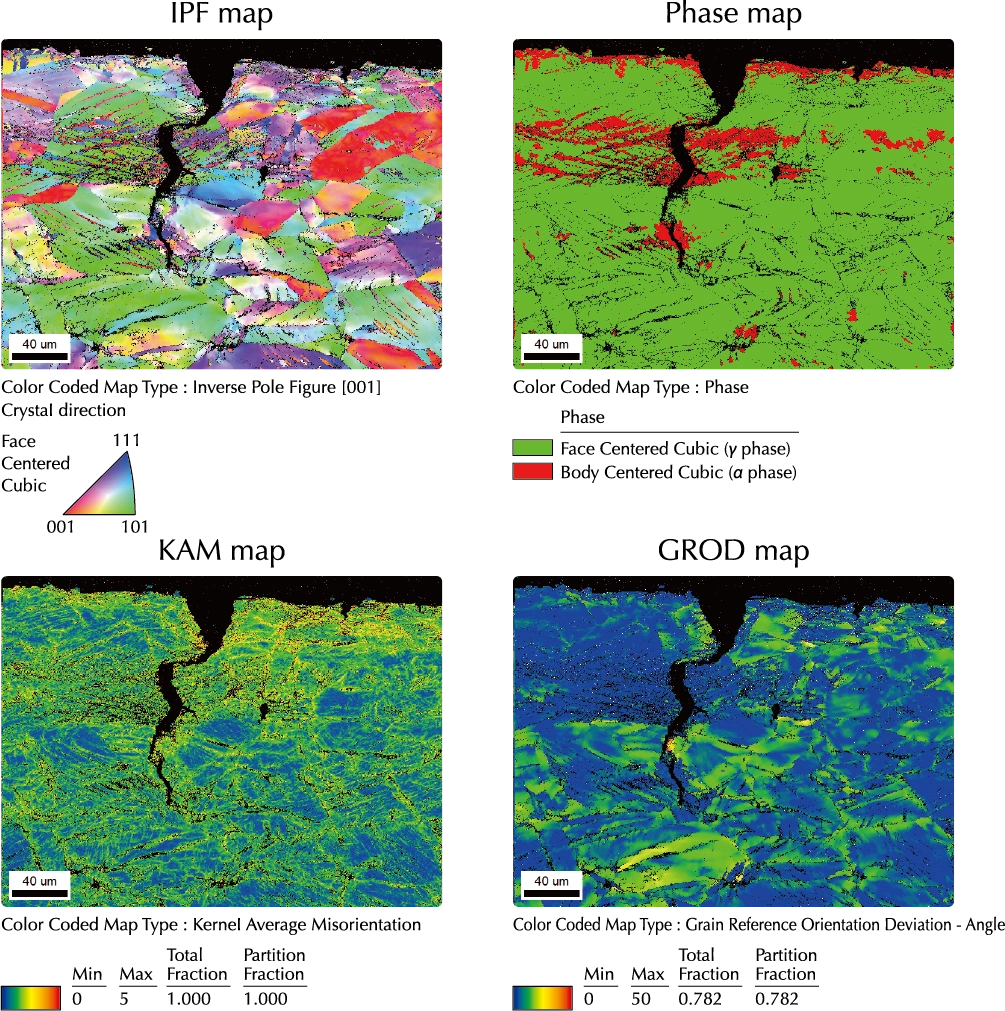

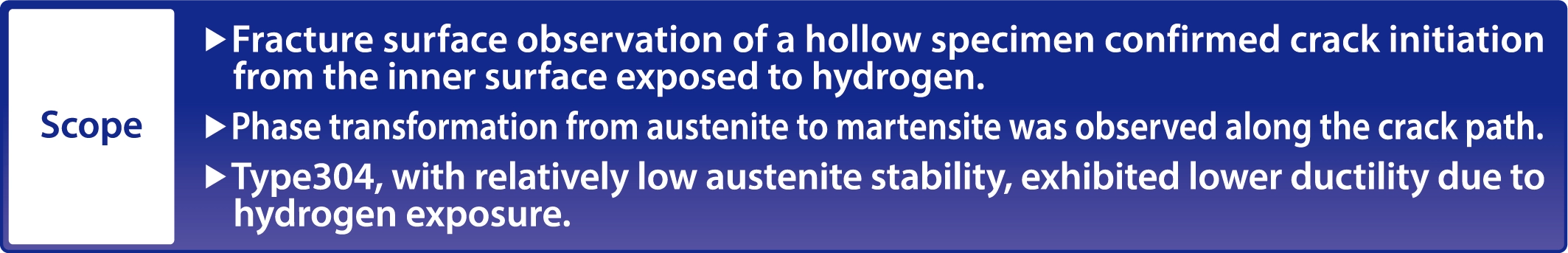

Analysis of Fractured Hollow Specimens Using Electron Backscatter Diffraction (EBSD)

Using scanning electron microscopy (SEM) to observe the fracture surface of tested hollow specimens revealed multiple secondary cracks in addition to the primary crack. This suggests that hydrogen embrittlement promotes localized crack initiation, leading to failure through multiple damage pathways.

Applying Electron Backscatter Diffraction (EBSD) provides detailed information on the microstructure near the fracture area. The resulting orientation maps are essential for understanding the mechanisms of hydrogen embrittlement.

*Scroll horizontally

Continuous Electrolytic H-charging for SSRT Test

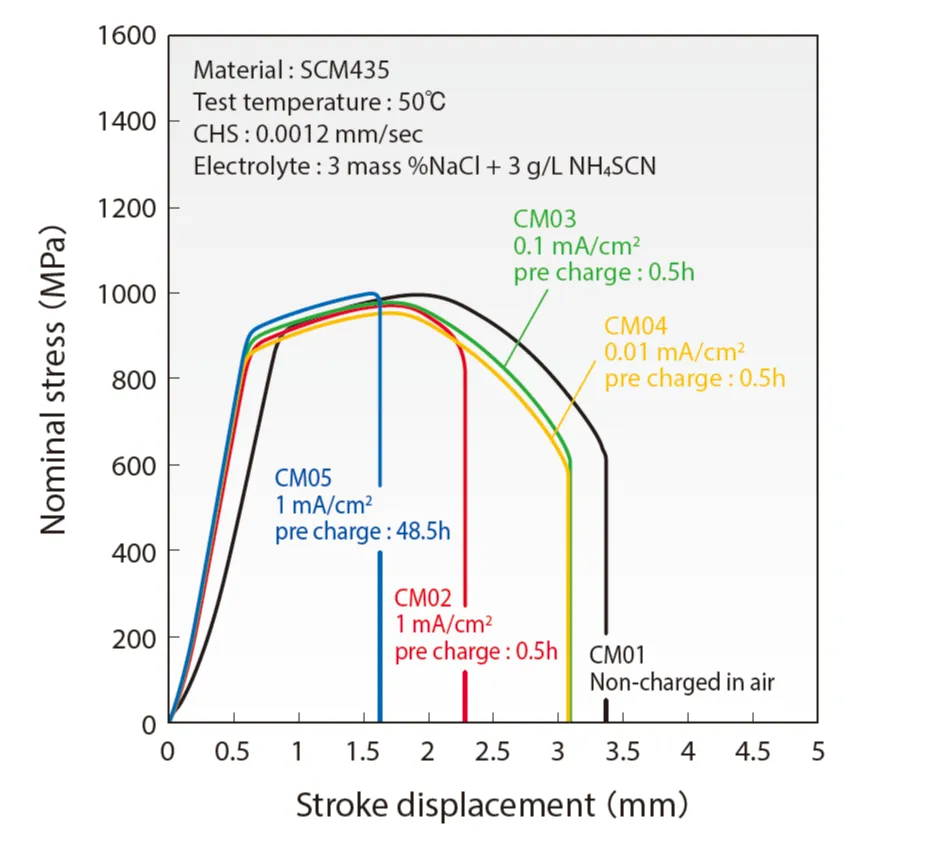

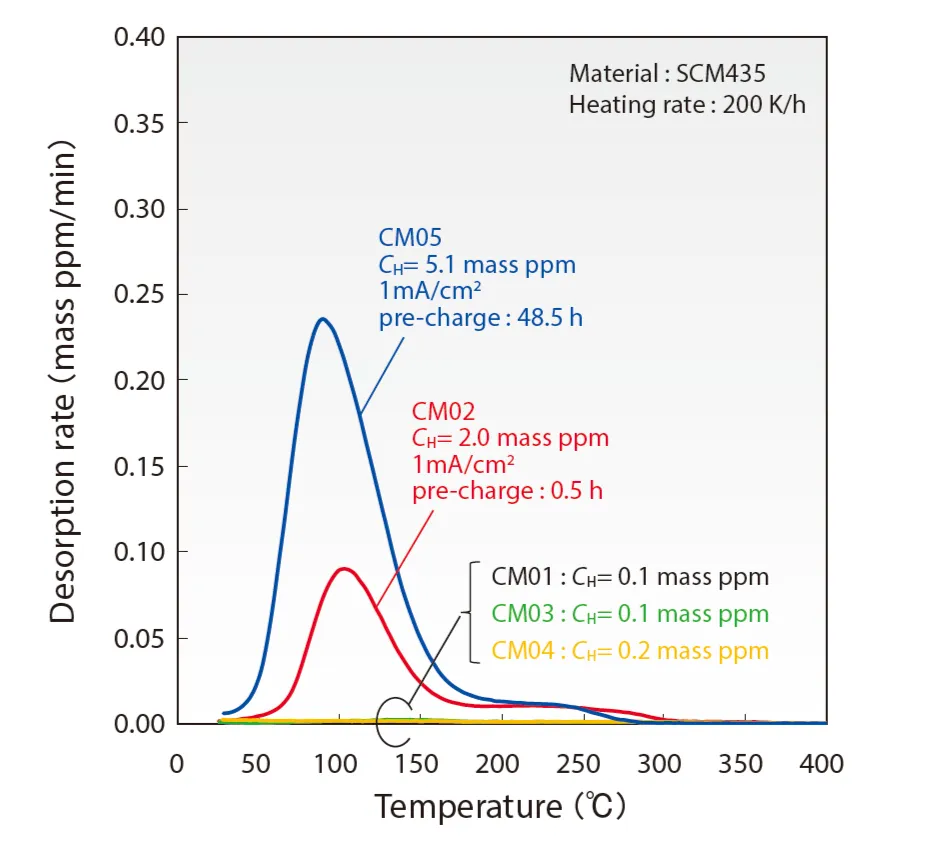

Electrolytic hydrogen charging is a method used to add hydrogen to metallic materials. The specimen is polarized in an aqueous solution, allowing hydrogen to permeate the material’s surface and diffuse into its interior. It has been primarily used to study hydrogen embrittlement and delayed fracture of steels under corrosive environments. Hydrogen embrittlement tends to increase with the hydrogen concentration in the steel. Electrolytic hydrogen charging allows us to simulate hydrogen effects in actual environments to evaluate the hydrogen resistance of steel.

At Kobe Material Testing Laboratory Co., Ltd., we faced the challenge of hydrogen desorption during tensile tests in the atmosphere conducted after hydrogen charging. The following section introduces our developed method for maintaining hydrogen charging during tensile tests, effectively solving this issue.

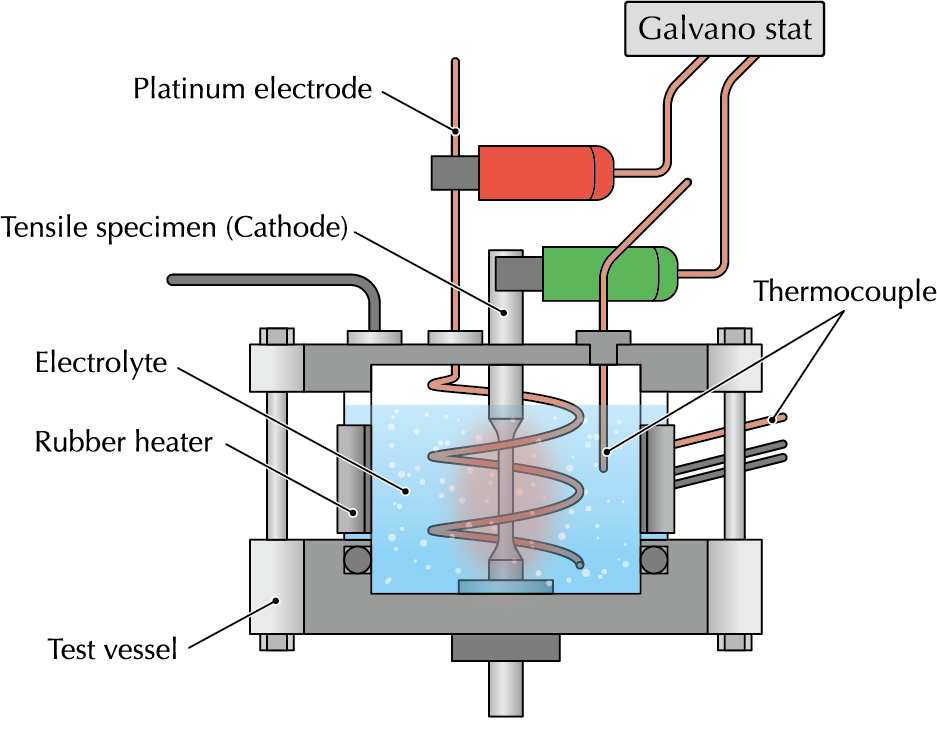

Experimental Setup of the Continuous Electrolytic Charging SSRT Testing Method

- SSRT testing is performed with a specimen hydrogen-charged using electrochemical reactions during the process.

- Optimal for evaluating hydrogen embrittlement, including delayed fracture in corrosive environments, with a wide range of parameter settings such as electrolyte composition, current value, and test speed.

- Hydrogen concentration analysis is conducted by immersing the fractured specimen in liquid nitrogen and store it without hydrogen desorption.

- Custom design and fabrication of experimental equipment are available.

Stress-Stroke Curves

Thermal Desorption Analysis (TDA) of Hydrogen

*Scroll horizontally

SSRT, Fatigue Life and Fatigue Crack Growth Tests

Under

100 MPa Class High Pressure Hydrogen Gas Environment

High pressure hydrogen gas vessels and piping are essential for hydrogen-energy related products and infrastructure, including FCV fuel tanks, hydrogen station refueling equipment, and large-scale hydrogen transportation and storage facilities. While these components enhance energy density and efficiency, they require specialized technologies and materials to handle the pressure safety. Strict safety standards and regulations necessitate extensive material testing in a high-pressure hydrogen gas environment. At Kobe Material Testing Laboratory Co., Ltd., we have established testing capabilities for SSRT, fatigue life, and fatigue crack growth tests under high pressure hydrogen gas environments. This was achieved by integrating a specially designed compact pressure vessel into a general-purpose hydraulic servo-type fatigue testing system.

New Test Method for Small-Sized Specimens

under High-Pressure Gaseous Hydrogen

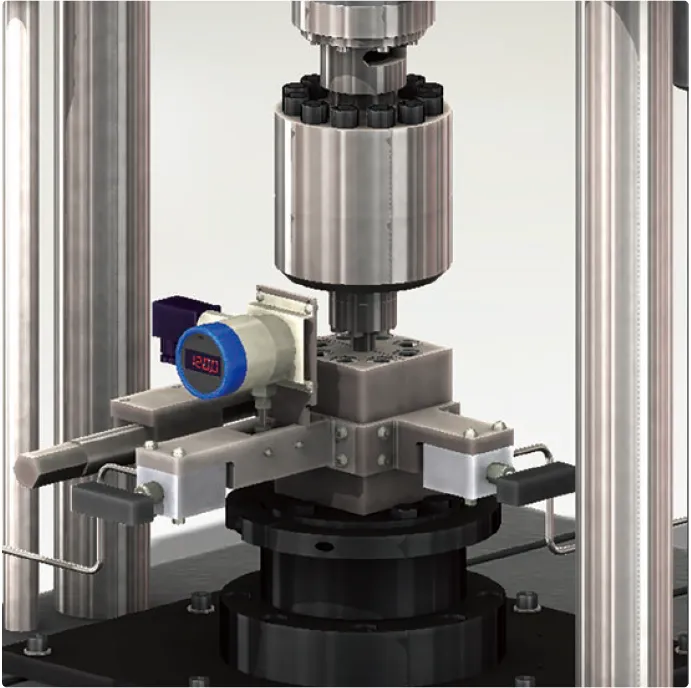

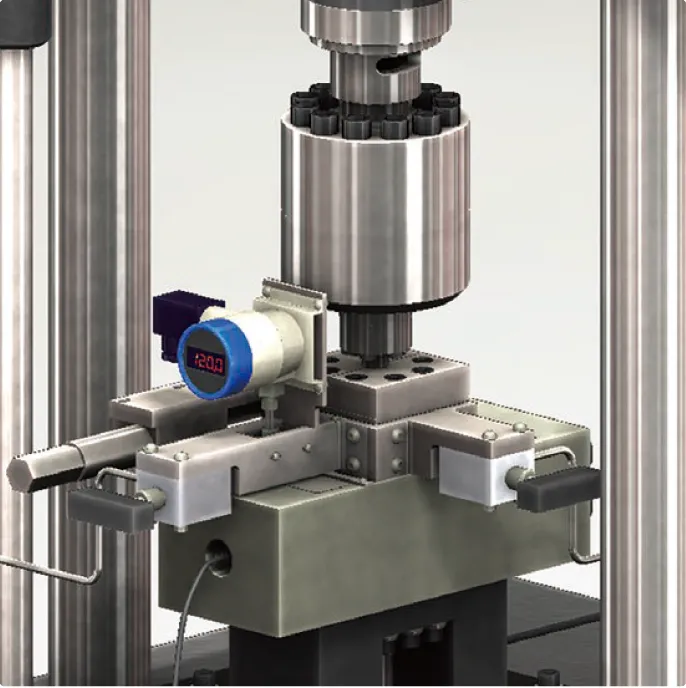

System for SSRT and fatigue life tests

System for fatigue crack growth and fracture toughness tests

Our dedicated explosion-proof test room has been registered as a High-Pressure Gas Production Facility in Hyogo Prefecture. Tests are conducted in full compliance with safety regulation by Japanese law, including gas detectors, forced exhaust fans, explosion-proof fluorescent lights, and regular voluntary inspections.

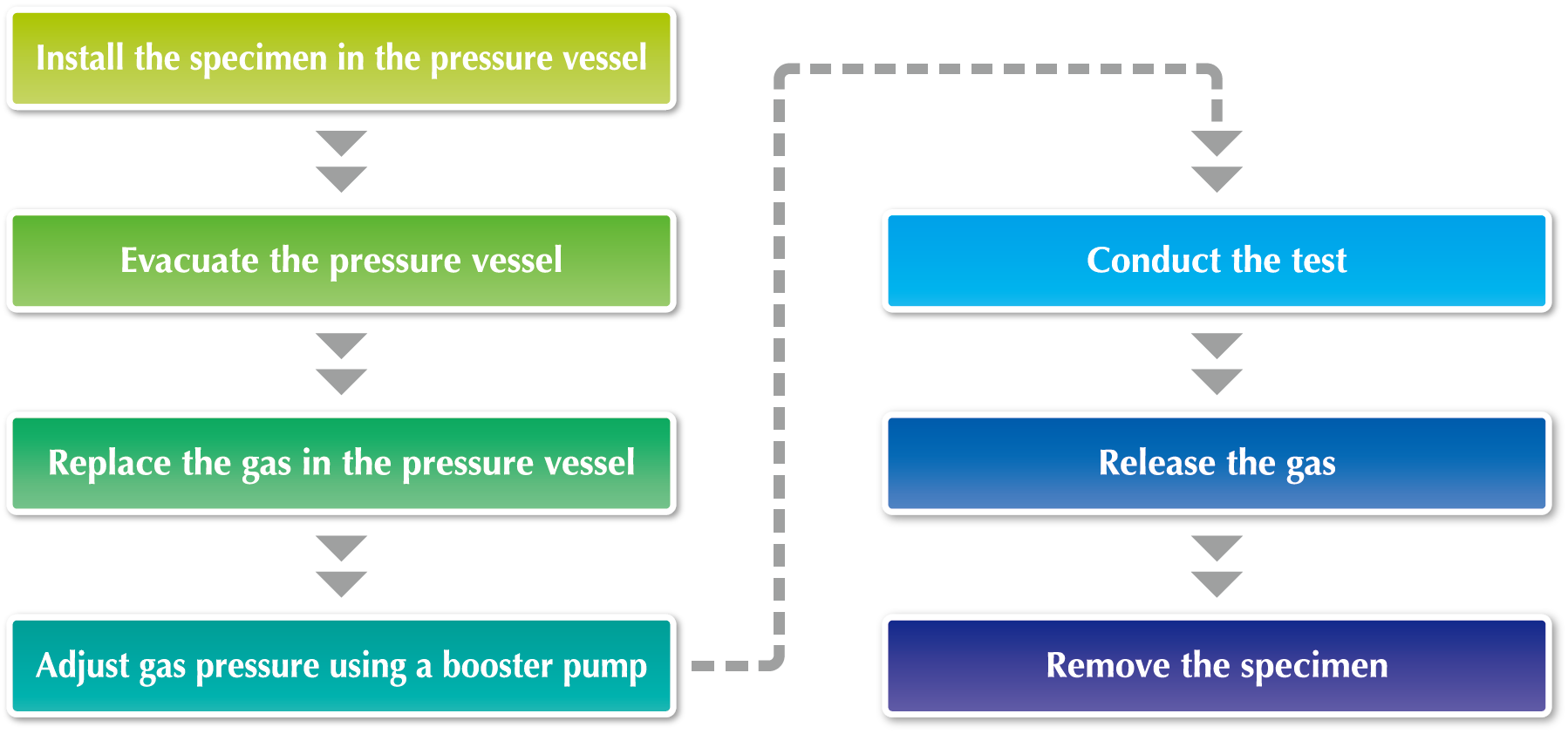

Test Procedure

Testing Performance in High Pressure Hydrogen Gas Environment

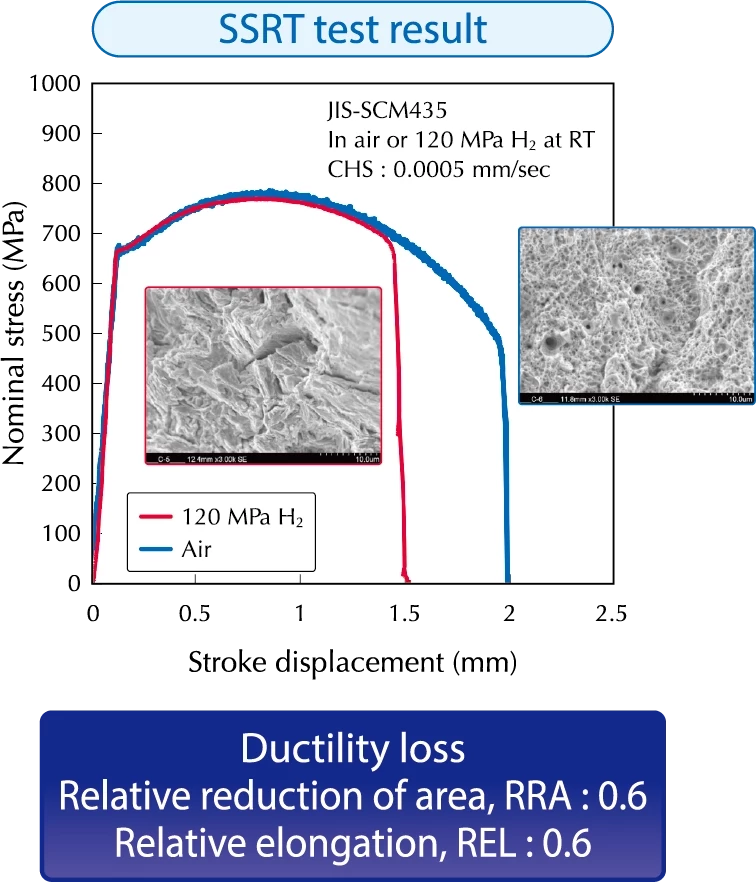

SSRT test result

Fatigue crack growth test result

Fatigue life test result

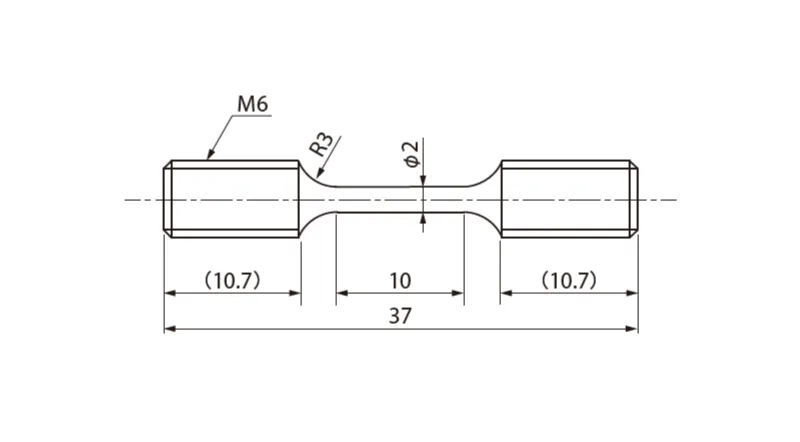

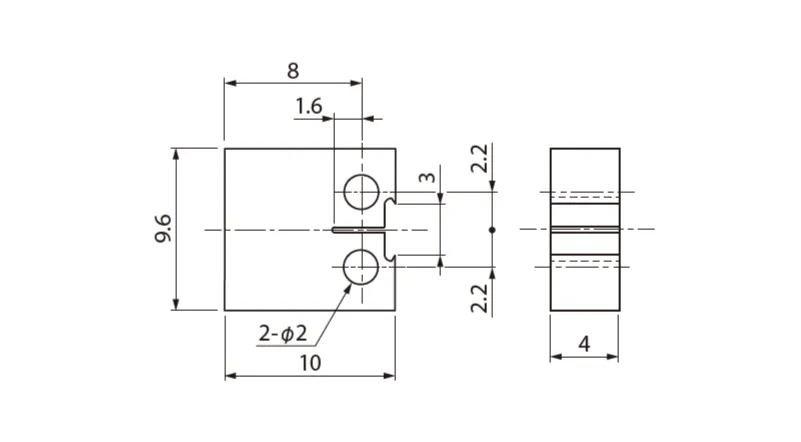

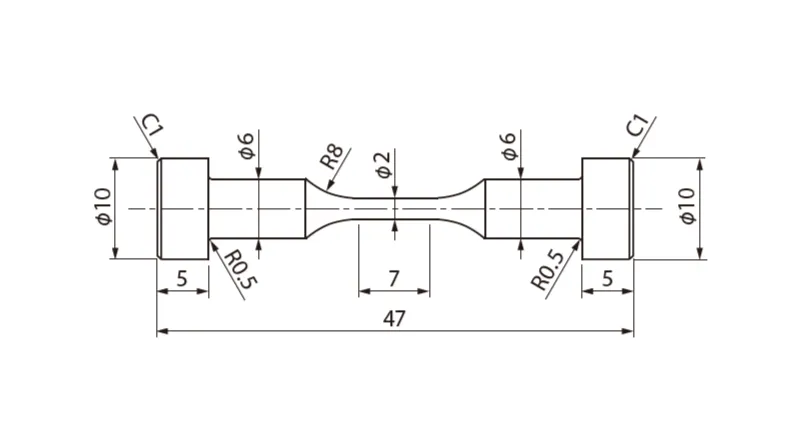

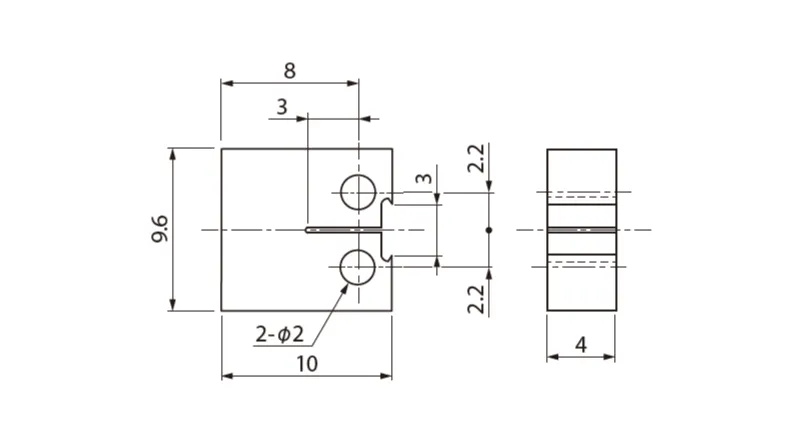

KMTL‘s Standard Specimen Designs

SSRT test specimen

CT specimen for fatigue crack growth test

Fatigue life test specimen

CT specimen for fracture toughness test

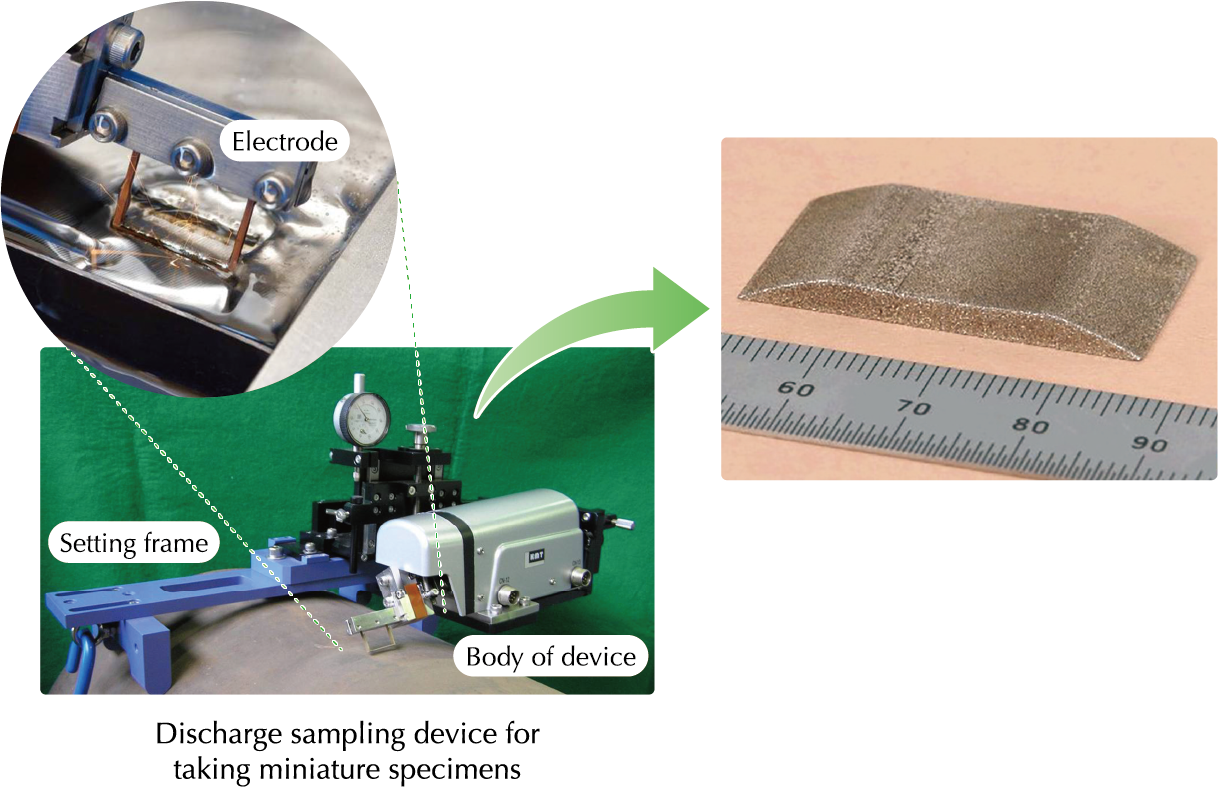

Core Technology of KMTL’s Miniature Testing Method

In all industrial fields, there is a need to take samples from actual products or components and conduct various material tests while simulating similar environments. However, limitations on the dimensions of materials that can be taken from actual machines often result in specimens that do not meet the size recommended by general test standards. We specialize in miniature testing technology, where small samples taken from actual components are machined into specimens and subjected to a range of testing methods. This technology has been adapted for high-pressure hydrogen gas environment, resulting in our original test method described in this document. For further details, please scan the QR code to explore our miniature testing services.

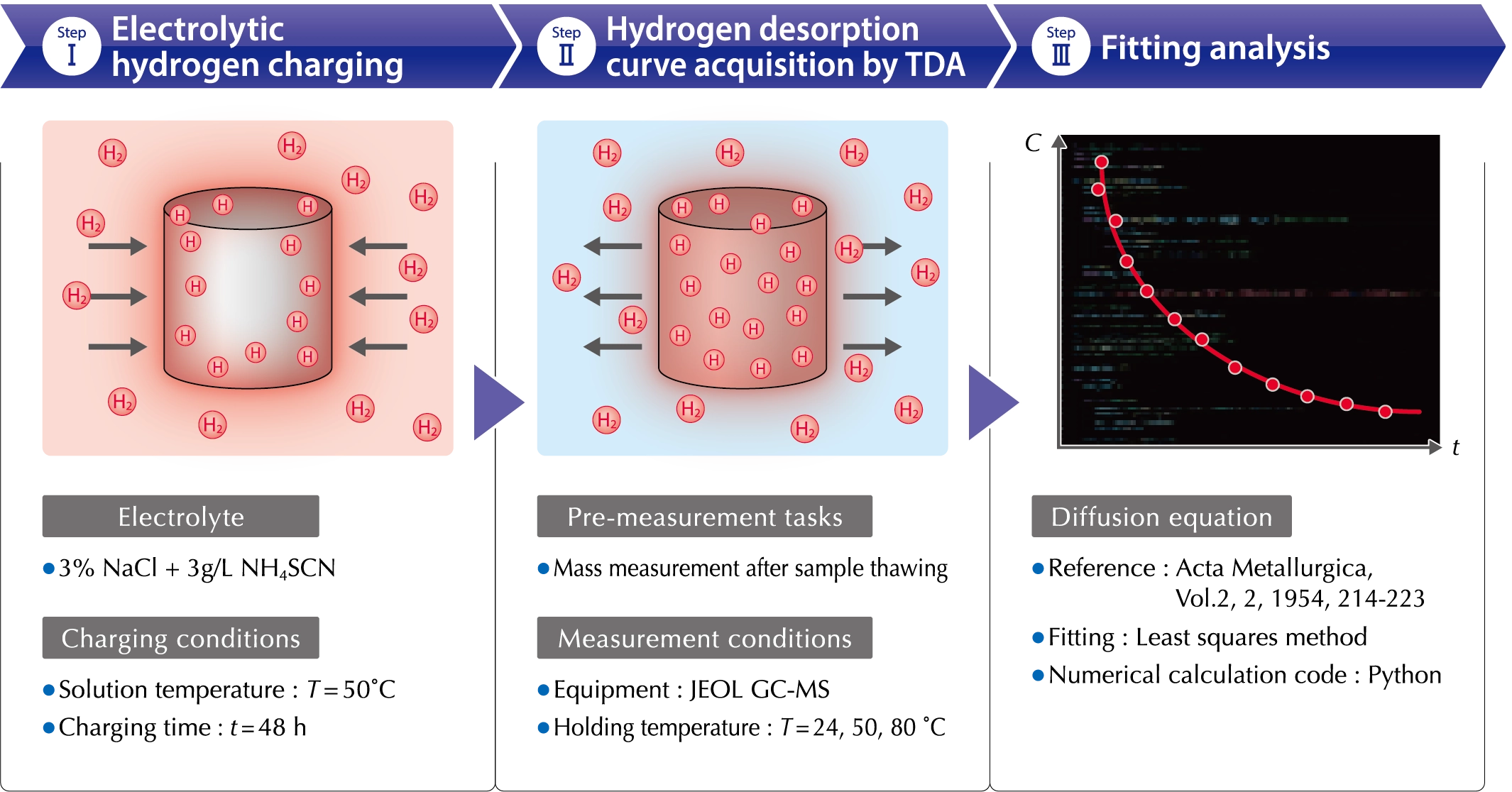

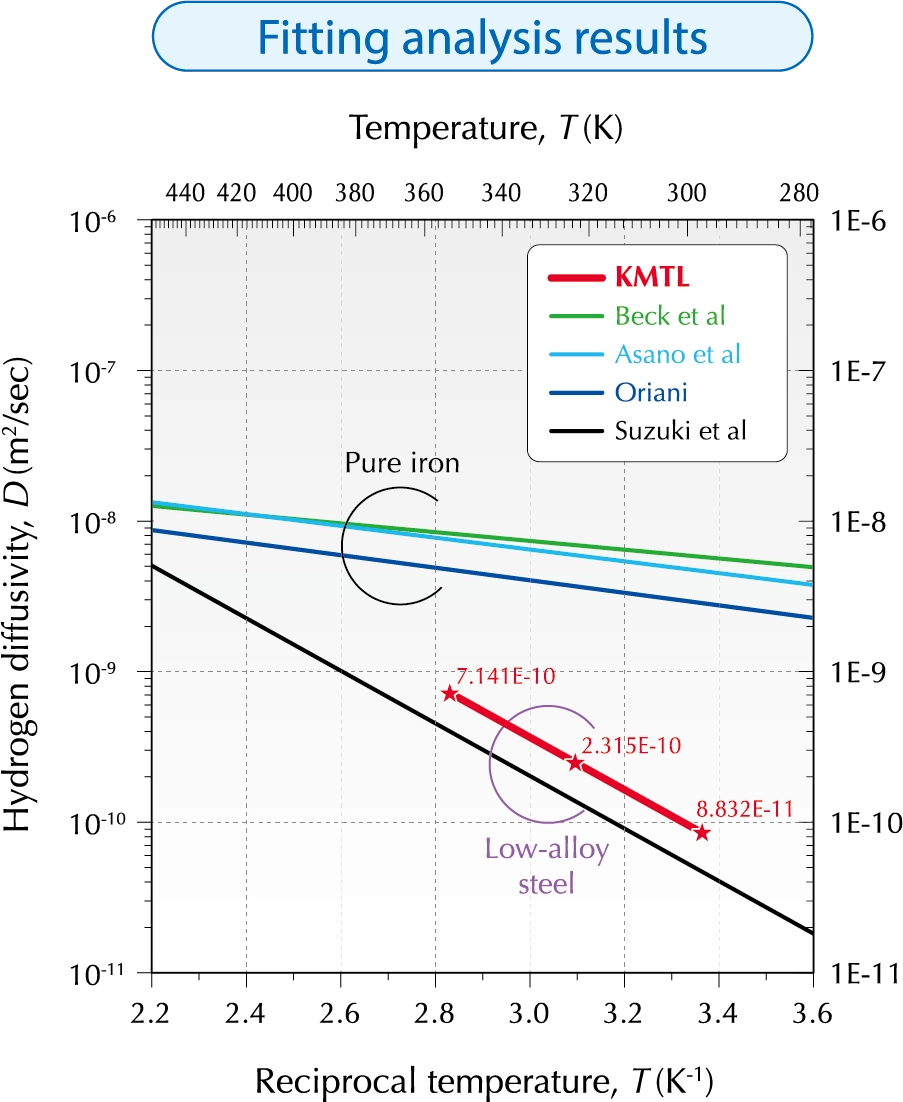

Measurement and Analysis of Hydrogen Diffusivity, D

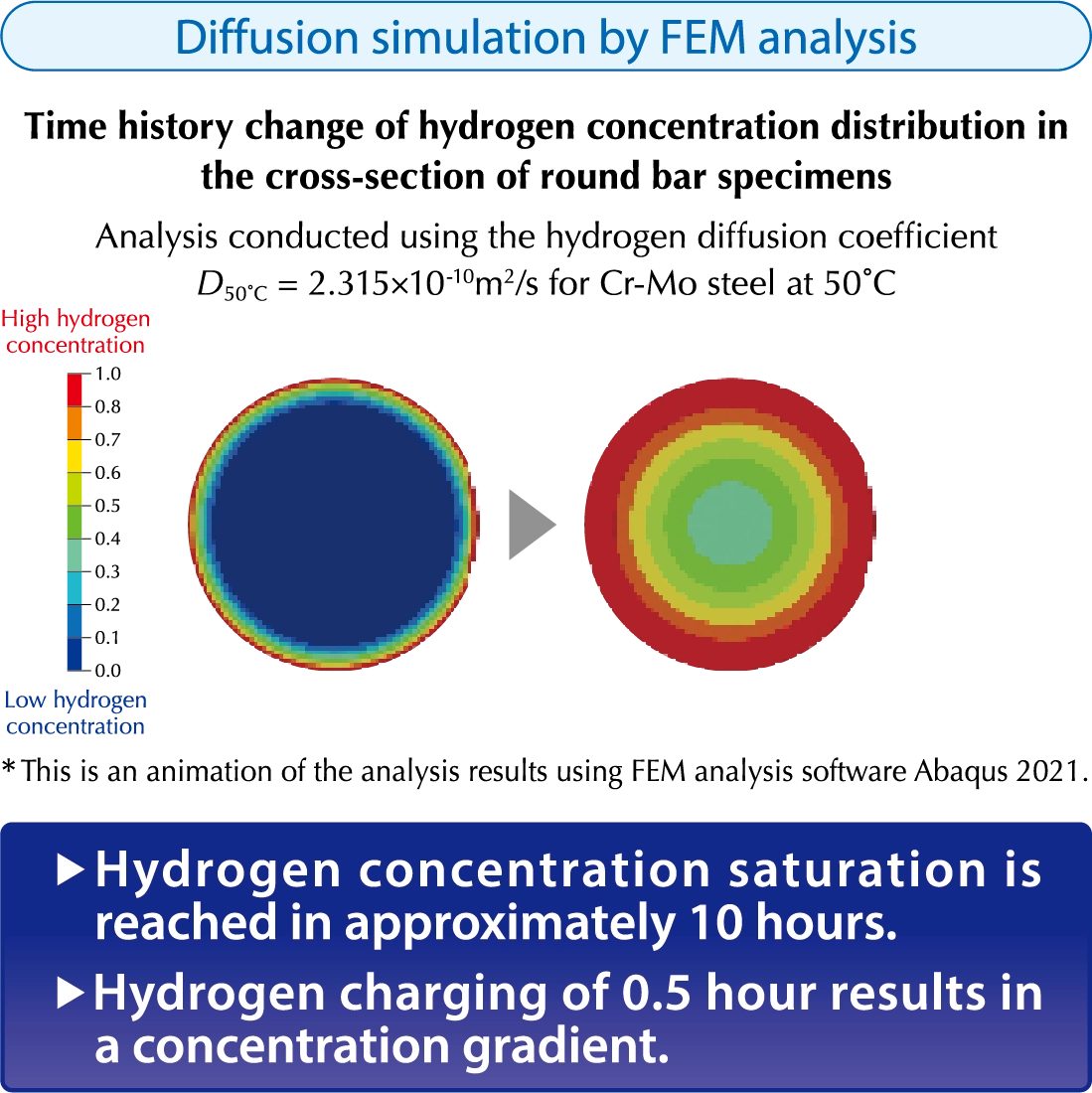

Hydrogen atoms in metals diffuse significantly faster than other solute atoms such as carbon. Many researchers identify hydrogen diffusion as a primary cause of hydrogen embrittlement. Kobe Material Testing Laboratory Co., Ltd. has developed an experimental method for determining hydrogen diffusivity (D). Hydrogen concentration distribution analysis using FEM, based on this hydrogen diffusivity is shown as follows.

Procedure for Hydrogen Diffusivity by Thermal Desorption Analysis (TDA)

*Scroll horizontally

Fitting analysis results

Diffusion simulation by FEM analysis

TEST SERVICE

Test Service

KMTL provides a wide range of testing services including fatigue and creep testing to support safety and security for society at large.