-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

OTHER SERVICE

SMALL PUNCH CREEP TEST EQUIPMENT

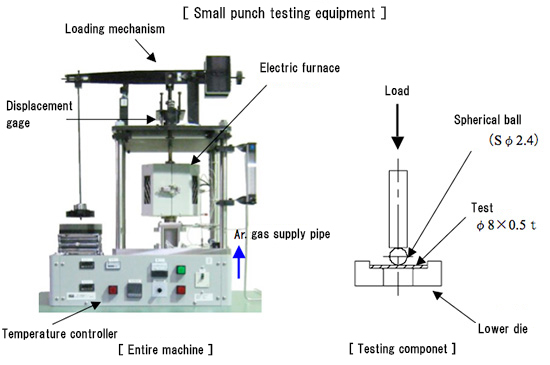

Small Punch Creep Testing Equipment

KMTL, jointly with Kyushu Electric Power Co., Inc., has developed the world’s most compact-sized and lightweight Small Punch Creep Testing Machine. This equipment enables creep testing to evaluate material deterioration with minimum amount of samples.

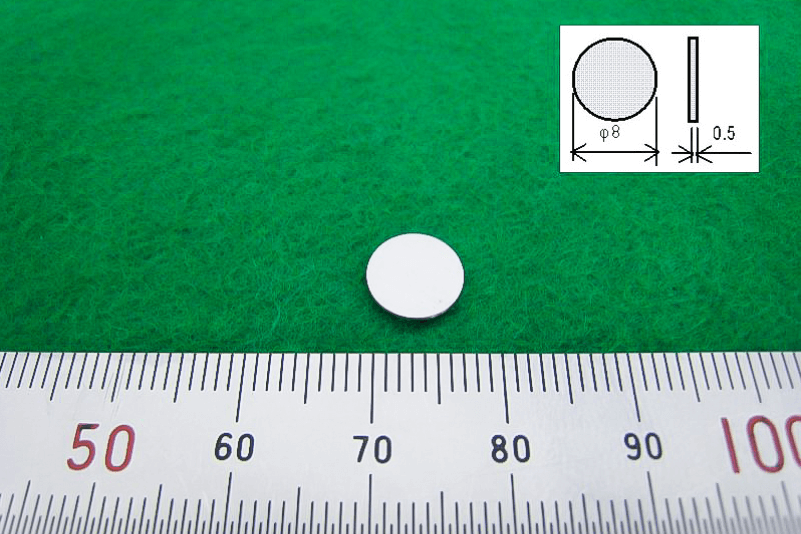

Non-destructive and destructive testing methods are used to evaluate heat-resisting members of high-temperature and high-pressure components in thermal power generation facilities, and, however, they conventionally require, for example, a 6-mm diameter bar specimen that significantly affects the component to be sampled. This equipment uses a miniature specimen (a disk 8-mm in diameter and 0.5 mm in thickness) machined from a sample material scooped from piping for residual life evaluation.

This development was highly regarded and won awards from The Japan Society of Mechanical Engineers Kyushu Branch and Thermal and Nuclear Power Engineering Society Kyushu Branch.

Outline

The small punch creep test is a type of miniature testing that obtain creep properties using a test specimen smaller than a one dime coin. For diagnosing the level of aging and deterioration of power generation equipment including boilers, creep testing is conducted using this machine with small amount of sample taken from the component surface.

The main body of the machine is the smallest and lightest, one tenth in size and one fifth in weight of the conventional equipment. Lever type loading system is employed. The specimen is set in the chamber with argon-gas atmosphere. Two pairs of displacement gages attached to the loading shaft increase measurement accuracy.

Comparison with a conventional specimen

Comparison with a conventional specimen

Small punch creep specimen (φ8 x 0.5t)

Small punch creep testing

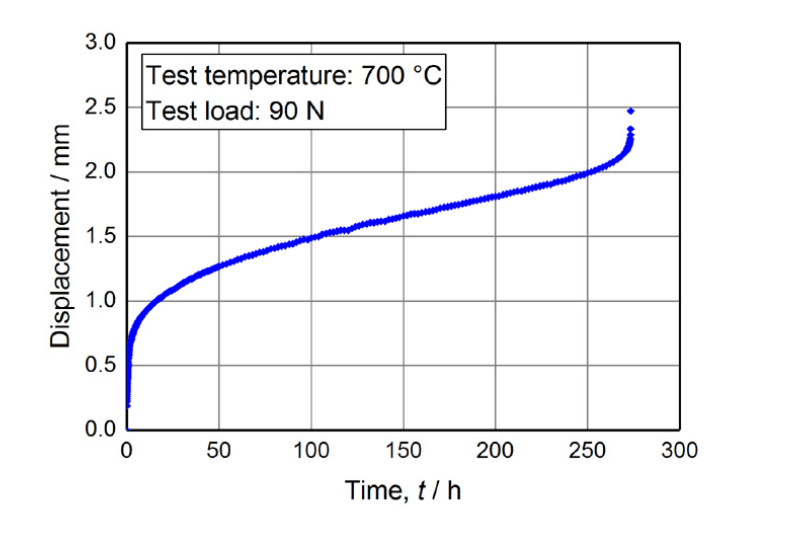

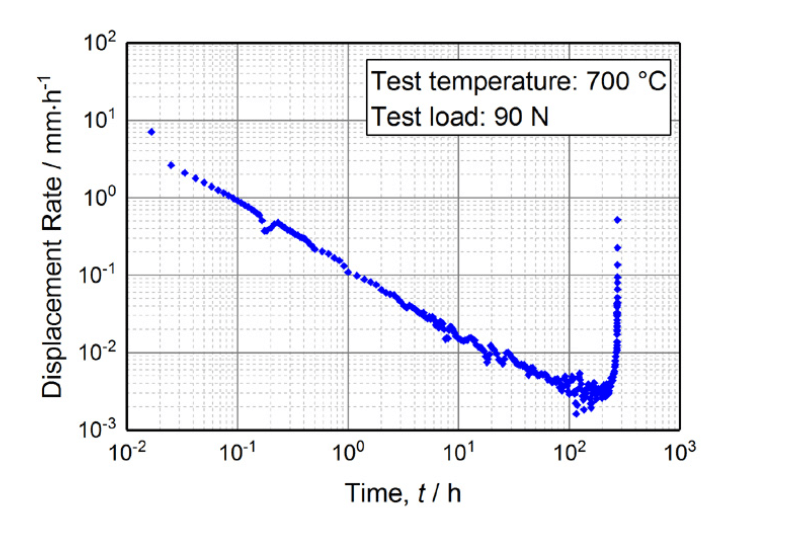

The time to rupture, creep curve, and creep rate are obtained from creep testing on a small punch creep testing machine.

Creep curve

Creep rate curve

TEST SERVICE

Other Service

KMTL also support the production of test pieces and various equipment required for testing and analysis and provide total support for material testing.

Test Specimen Preparation

Sophisticated Machining Skills

Sampling and Machining Miniture Test Specimens