-

Test Service

-

Analysis Service

-

Accreditations/Approvals

- First time visitors

-

- Contact Contact

- JAPANESE

TEST SERVICE

RESIN PROPERTIES

Resin Properties

Plastic materials are susceptible to temperature and humidity change as compared to metals. In a special testing room with a controlled temperature of 23℃±2℃ and relative humidity of 50%±5% to accommodate high-accuracy static and thermal property testing, we conduct wide range of plastic material testing to ISO, ASTM, JIS and other standards including static and thermal property testing.

Tensile test with contactless extensometer

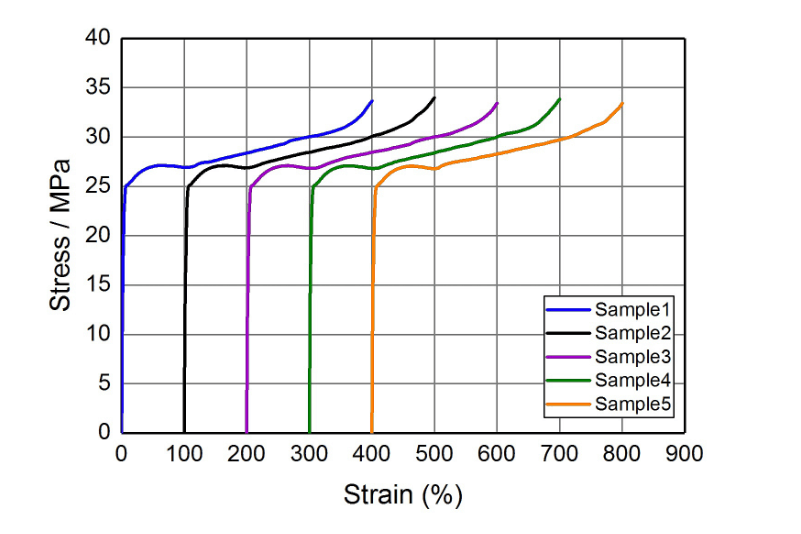

Tensile strength chart

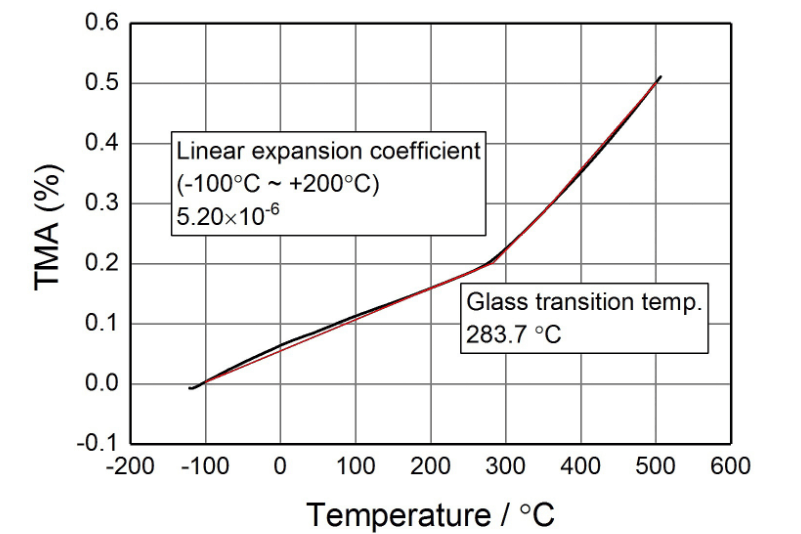

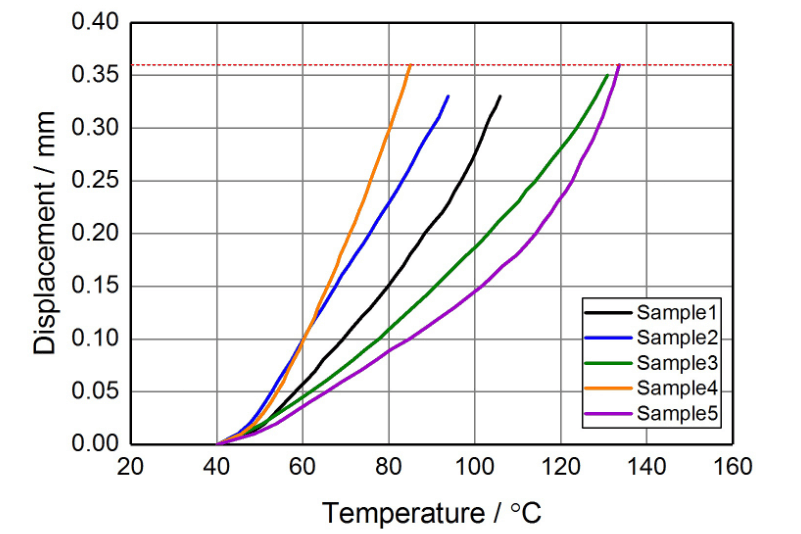

Thermal mechanical analysis chart

Load deflection temperature chart

Expertise

| Tensile test | 10kN, 1kN |

|---|---|

| High/low temperature tensile test | 50kN: -60℃〜250℃ 100kN: -180℃〜320℃ |

| Charpy impact test | 0.5J〜15J |

| Izod impact test | 1J〜22J |

| Rockwell hardness test | HRR, HRL, HRM |

| Shore hardness test | HDD, HDA |

| Tensile modulus test | |

| Density measurement test | |

| Bend test |

| Brittleness temperature test | -50℃〜20℃ |

|---|---|

| Load deflecting temperature test | Max 300℃ |

| Melt flow rate test | |

| Vicat softening temperature test | |

| Thermomechanical analysis test |

Standards

| JIS K 7161,7162:1994 |

| ISO 527-1,2:1993 |

| ASTM D638 |

| JIS K 7197 |

| ISO 11359-1,2 |

| JIS K 7110 |

| ISO 180 |

| JIS K 7171 |

| ISO 178:2001 |

| ASTM D790 |

| JIS K 7111-1 |

| ISO 179-1 |

TEST SERVICE

Test Service

KMTL provides a wide range of testing services including fatigue and creep testing to support safety and security for society at large.